Unlocking the Power of Emflex

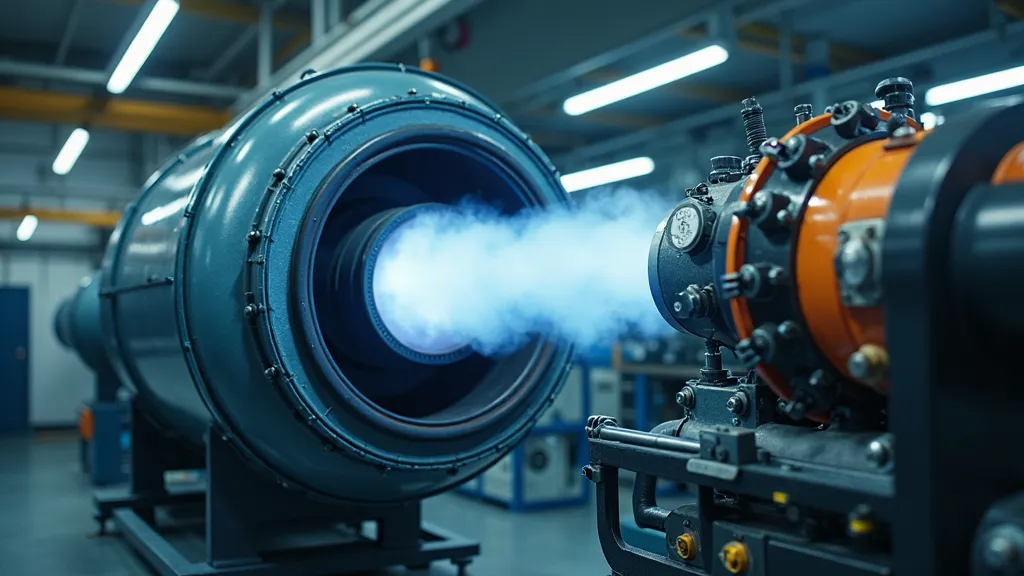

This article explores Emflex, an advanced technology transforming the manufacturing landscape. Emflex is a key player in the field, renowned for its flexibility, efficiency, and adaptability, which significantly enhance production processes. Its implementation has redefined the standards of precision and reliability in various industrial sectors. The details below offer insights from the industry perspective, highlighting its impact and future potential.

Introduction to Emflex

In the rapidly evolving landscape of manufacturing technology, Emflex stands as a pivotal player, offering unparalleled flexibility and efficiency. The significance of Emflex lies in its ability to adapt to diverse manufacturing needs, streamlining operations and enhancing productivity. As industries strive for greater precision and reliability, Emflex emerges as a cornerstone technology, reshaping how goods are produced and delivered. The increasing competition in various markets requires manufacturers to seek innovative solutions that provide not only speed but also quality and sustainability. This is where Emflex truly demonstrates its worth, as it encapsulates the essence of modern manufacturing.

The Unique Advantages of Emflex

Emflex brings a suite of advantages that significantly boost manufacturing performance. Its modular design allows for easy integration into existing systems, ensuring seamless operation without the need for extensive overhauls. This feature is particularly important for businesses aiming to enhance their productivity without incurring substantial capital expenditure on new equipment. Moreover, Emflex's cutting-edge technology offers precision control over production processes, reducing errors and waste. This precision not only enhances product quality but also drives down operational costs, creating a competitive edge for businesses that employ it. Through sophisticated sensors and real-time data analysis, Emflex systems can adjust processes dynamically, further enhancing efficiency.

Furthermore, Emflex's adaptability extends to various industries, from automotive to electronics, demonstrating its versatility and broad applicability. For example, in the automotive sector, Emflex can facilitate the production of complex components with intricate designs, while in electronics, it can manage tight tolerances required for circuit boards. As technological demands evolve, Emflex's capability to adapt and innovate ensures its relevance and effectiveness across multiple sectors. The confluence of different industries embracing Emflex not only boosts their individual performances but also sets a standard for operational excellence that others are likely to follow.

Emflex: A Catalyst for Industry 4.0

Emflex is instrumental in the transition towards Industry 4.0, characterized by smart manufacturing and interconnected systems. With the advent of the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, manufacturing is undergoing a revolutionary shift. Emflex stands at the forefront of this transformation, enabling factories to implement smart technologies that enhance automation and connectivity. By facilitating automation and data exchange, Emflex enables factories to become more agile and responsive to market changes, responding more swiftly to customer demands and market fluctuations. Its integration with digital technologies like IoT and AI allows for real-time monitoring and decision-making, optimizing production schedules and maintenance tasks.

Moreover, Emflex supports sustainable manufacturing practices by optimizing resource use and minimizing environmental impact. With rising global concerns over climate change and sustainability, manufacturing processes need to adapt by becoming more resource-efficient. Emflex’s efficient energy management and waste reduction capabilities align with global sustainability goals, making it a preferred choice for eco-conscious manufacturers. By reducing energy consumption and maximizing productivity, businesses can not only lower their operating costs but also enhance their brand image by aligning with consumer expectations concerning sustainability.

Detailed Analysis: Benefits and Challenges

The benefits of Emflex are manifold, but implementation is not without challenges. The initial adoption of such advanced technology may come with high setup costs and a steep learning curve for personnel. Industries adopting Emflex must consider initial setup costs and the need for skilled personnel to manage and operate these advanced systems. Additionally, businesses must ensure they have the necessary infrastructure in place, including IT support, cybersecurity measures, and a robust data management system to handle the influx of information generated by Emflex technologies.

Despite these considerations, the significant payoffs—such as improved efficiency, reduced overheads, and enhanced product quality—validate the investment. To maximize the benefits of Emflex, companies should conduct thorough assessments of their operational needs and engage in strategic planning to integrate this technology seamlessly. Furthermore, building a robust infrastructure to support Emflex and investing in training programs for workforce adaptation are crucial steps toward successful implementation. Providing adequate training and support will not only empower employees to utilize the technology effectively but will also foster a culture of innovation and continuous improvement within the organization.

The Future of Emflex in Manufacturing

As technology continues to advance, the potential for Emflex in manufacturing is immense. Emerging trends such as additive manufacturing, also known as 3D printing, and smart factories will see increased integration of Emflex, driving innovations in product design and production methodologies. Manufacturing companies are increasingly looking toward techniques that allow for greater customization and shorter lead times, and Emflex is uniquely positioned to meet these demands. The continuous evolution of Emflex technology promises to keep pace with industry demands, ensuring its role as a transformative tool in manufacturing.

Furthermore, the future of Emflex includes exciting possibilities. Enhanced AI capabilities might introduce new predictive maintenance solutions, significantly reducing downtime and ensuring that production processes run smoothly and efficiently. Developments in materials science may allow Emflex to work with even more diverse materials, enabling the creation of advanced components that push the boundaries of manufacturing capability. With its ability to enhance operational efficiency and product quality, Emflex is set to remain a vital component of modern manufacturing strategies. Its ongoing development will likely introduce even greater capabilities, expanding its application scope and further revolutionizing the manufacturing landscape.

Comparison Table: Emflex vs Traditional Manufacturing Technologies

| Aspect | Emflex | Traditional Technologies |

|---|---|---|

| Integration | Seamless and modular | Often requires extensive adjustments |

| Precision | High, with reduced errors | Subject to higher error margins |

| Cost Efficiency | Good savings | Higher ongoing operational costs |

| Flexibility | Highly adaptable | Limited adaptability |

| Scalability | Easy to scale up or down | Often requires additional investments |

| Data Integration | Real-time data-driven | Periodic data collection |

| Maintenance | Predictive and proactive maintenance | Reactive maintenance |

FAQs

- What industries benefit the very from Emflex?

Industries such as automotive, electronics, aerospace, and pharmaceuticals benefit greatly due to Emflex's precision, flexibility, and efficiency in complex manufacturing processes. In the automotive sector, for example, Emflex systems can streamline the production of intricate parts, improving time-to-market while maintaining high safety standards.

- Is Emflex suitable for small-scale operations?

Yes, Emflex's modular design allows it to be cost-effective and scalable, making it ideal for both small and large operations. Small manufacturers, especially those looking to compete with larger firms, can leverage Emflex technology to enhance efficiency and product quality without needing significant capital outlays.

- How does Emflex contribute to sustainable manufacturing?

Emflex optimizes resource use by reducing energy consumption and waste generation, aligning with sustainability goals by promoting cleaner and more efficient manufacturing practices. For instance, it allows for the recycling of materials in processes and minimizes waste by ensuring that production runs within optimal efficiency parameters.

- What are the initial setup considerations for Emflex?

Businesses need to consider the cost of upgrading infrastructure and training personnel, aimed at ensuring a smooth transition to using Emflex technology. It often involves a comprehensive review of existing systems and processes, engaging stakeholders, and potentially significant investments in new hardware and software capabilities. Additionally, cybersecurity measures must be prioritized to protect sensitive manufacturing data.

- Can Emflex technology be customized for specific needs?

Absolutely. Emflex systems are designed to be highly customizable, meaning that organizations can tailor the technology to meet their specific operational requirements. This flexibility allows businesses to adopt functionalities that cater directly to their sector, enhancing usability and performance.

- What kind of support does Emflex offer post-implementation?

Emflex offers a range of support services post-implementation, including technical assistance, training for staff, and ongoing maintenance programs. These services are crucial to ensure that businesses can fully utilize the capabilities of Emflex technology and achieve continuous optimization in their manufacturing processes.

- How do businesses evaluate the ROI of implementing Emflex?

Businesses typically evaluate the return on investment (ROI) of Emflex by analyzing the reduction in operational costs, improvements in product quality, and increases in production efficiency. Other factors may include decreases in time-to-market due to streamlined processes and enhanced flexibility that allows for quick adaptation to changing market demands.