Understanding IHM SCADA Systems

IHM SCADA systems are central to modern industrial automation, enabling seamless monitoring and control across various sectors. Originating in the 20th century, their development reflects the advances in technology and efficiency in processes, significantly enhancing productivity and operational safety in industries worldwide.

Introduction to IHM SCADA Systems

Industrial automation has witnessed significant advancements over the years, prominently featuring the evolution of IHM SCADA systems. This technology represents a critical component in the management and control of industrial processes, seamlessly integrating human input with automated monitoring systems to ensure efficient operations. The increasing complexity of industrial environments requires sophisticated systems that can not only handle vast amounts of data but also provide actionable insights in real-time. IHM SCADA systems excel at fulfilling these requirements, enabling industries to optimize their processes and make informed decisions quickly.

The Core of IHM SCADA

IHM SCADA, an acronym for "Interface Homme Machine Supervisory Control and Data Acquisition," blends two integral concepts: the human-machine interface (HMI) and SCADA systems. The HMI provides operators with a visual representation of the processes, while SCADA facilitates the monitoring and control of industrial operations. Together, these systems optimize performance and safety by providing real-time insights and control capabilities. Beyond mere data presentation, advanced HMIs offer interactive features that allow operators to manage systems remotely, enhancing operational flexibility. As we delve deeper into IHM SCADA, we can appreciate how these systems contribute not only to operational efficiency but also to strategic decision-making in highly regulated environments.

Historical Perspective

The journey of SCADA systems started in the mid-20th century, transforming traditional manual monitoring methods into more streamlined and automated processes. Initially, these systems were primitive, offering basic data collection and display features. Over decades, with the advent of computers and digital technology, SCADA systems have become sophisticated, offering dynamic interfacing and advanced analytics. In the early days, operators would rely heavily on paper charts and manual logs, a method fraught with inefficiencies and errors. The introduction of basic telemetry in the 1960s marked the beginning of remote monitoring capabilities. With it came the realization of how crucial automation could be in processing large data sets for improved decision-making.

The 1980s and 1990s witnessed a significant leap in SCADA technology with the introduction of personal computing, which paved the way for user-friendly graphical interfaces. This not only made it easier for operators to interpret data but also reduced response times during critical situations. As the technology continued to advance, the introduction of networking capabilities transformed SCADA systems into integrated hubs for data analysis, control, and reporting. This evolution has led us to the current state of IHM SCADA systems, which are characterized by their ability to connect with various industrial control systems and harness the power of data analytics to drive efficiency and safety.

Modern Applications of IHM SCADA

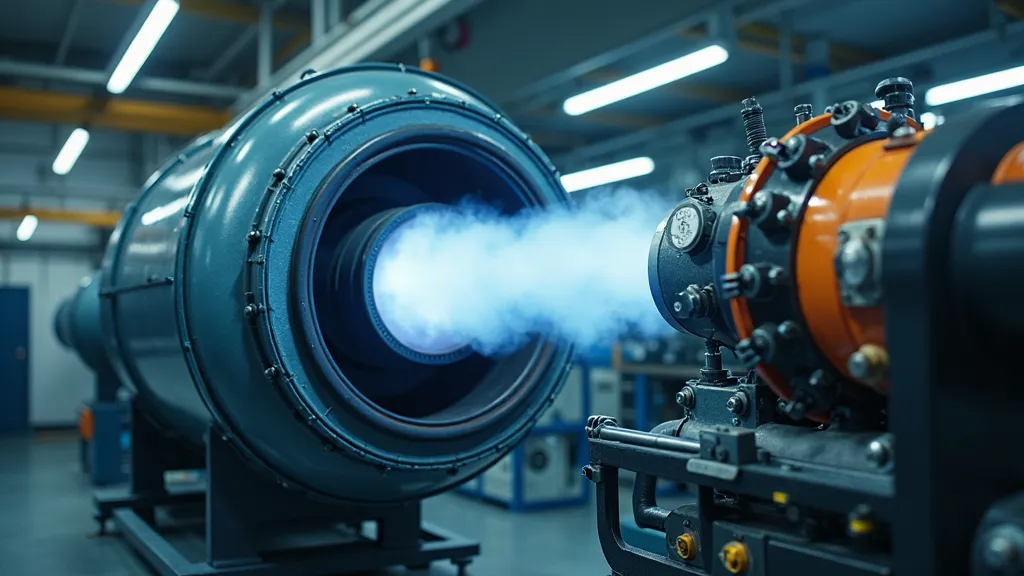

Today's IHM SCADA systems are pivotal in diverse sectors such as energy, manufacturing, water management, and telecommunications. For example, in energy management, they help in monitoring electrical grids and pipeline systems, ensuring a seamless supply of resources while detecting anomalies before they escalate into major issues. In factories, these systems enhance productivity by managing equipment performance and ensuring compliance with safety standards. Moreover, in water management, SCADA systems are employed for monitoring reservoir levels, water quality, and distribution systems, enabling prompt action to avoid shortages or contamination.

As digitalization continues to infiltrate industries, the wireless communication capabilities of modern SCADA systems offer even greater flexibility, allowing for mobile monitoring and control. Operators can access data remotely, respond to alarms via mobile devices, and manage processes through the cloud, significantly enhancing operational efficacy. This capability is particularly important in sectors where operational conditions fluctuate rapidly and the ability to react in real-time is critical to mitigate risks and enhance service delivery. Each application of IHM SCADA systems serves to illustrate their versatility and critical role in managing complex industrial ecosystems.

Technological Components of IHM SCADA

A typical IHM SCADA system encompasses several components, each contributing to the system's overall functionality and performance:

- Supervisory Computers: These are central to processing data and executing command sequences, providing the oversight necessary for comprehensive system management. They aggregate data from various sources, provide visualization tools for operators, and can trigger automated responses based on predefined criteria.

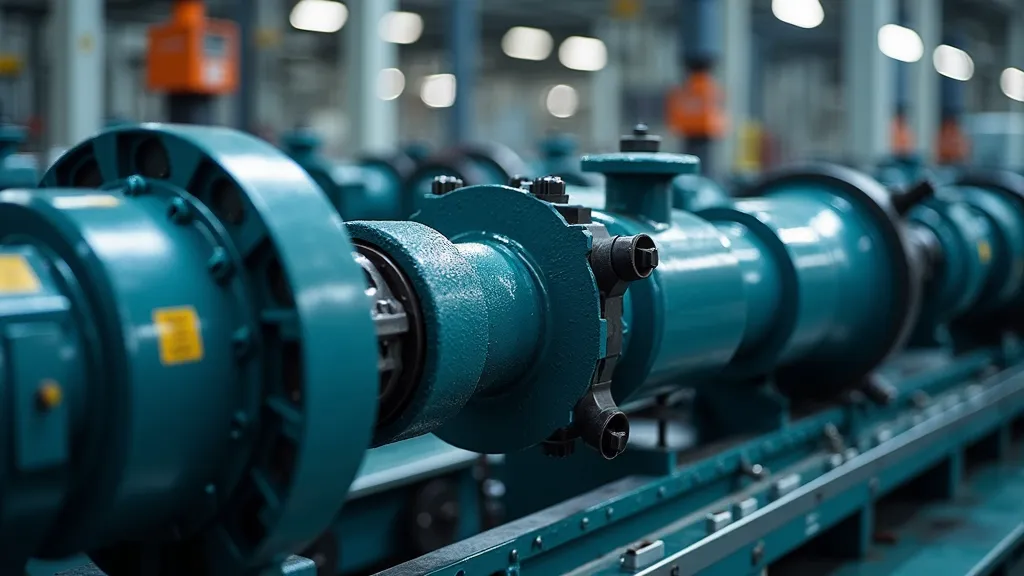

- Remote Terminal Units (RTUs): RTUs connect to sensor systems to gather data and relay it to the central SCADA system for processing and analysis. These devices are designed to withstand harsh industrial environments, often equipped with robust networking capabilities to ensure seamless data transmission, even over long distances.

- Programmable Logic Controllers (PLCs): These are crucial for controlling machinery, offering the necessary flexibility and scalability to meet the demands of various industries. PLCs can be programmed to perform specific control functions and integrate with various input and output devices from sensors to actuators.

- Communication Infrastructure: Ensures seamless data exchange between the supervisory station and remote devices, maintaining the integrity and speed of information flow. Modern communication protocols, such as MQTT and OPC UA, are widely used for effective and efficient data exchange.

- Data Acquisition Devices: These tools collect the necessary input from sensors placed throughout the facility for real-time processing. Effective data acquisition forms the backbone of any SCADA system, as it ensures that accurate and timely information is available for decision-making.

In addition to the core components, the integration of Artificial Intelligence (AI) and machine learning within SCADA systems is revolutionizing data processing and analysis. By applying advanced algorithms to historical data, these systems can now predict failures, optimize performance, and recommend maintenance schedules. This not only enhances operational reliability but also reduces downtime and maintenance costs, creating a significant return on investment for organization-wide SCADA deployment.

Market Trends and Predictions

As of recent analyses, the IHM SCADA system market is poised for expansion, propelled by the increased demand for automation and advanced analytics. Innovations in cloud computing, Artificial Intelligence (AI), and the Internet of Things (IoT) are further driving this growth. Industry reports project a compound annual growth rate (CAGR) in the range of 6% to 8% over the next five years, underscoring the increasing reliance on these systems for operational excellence. Furthermore, the emergence of cybersecurity threats in an increasingly digital world is prompting industries to prioritize robust security features within their SCADA offerings.

One of the significant trends affecting the industry is the shift towards cloud-based solutions, which promise enhanced scalability and lower upfront costs. Businesses are increasingly attracted to the idea of managing SCADA systems remotely without the need for extensive on-premises infrastructure. This shift is particularly appealing to small and medium-sized enterprises (SMEs) that may lack the resources for large-scale IT investments. Furthermore, the evolution of IoT and smart devices is leading to the development of more interconnected systems, allowing for unprecedented data exchange and insights. This interconnectedness brings about the potential for "smart manufacturing" environments, where IHM SCADA systems play a crucial role in facilitating seamless operations across diverse platforms.

Comparison Table of IHM SCADA Suppliers

| Supplier | Unique Features | Pricing Model |

|---|---|---|

| Company A | Cloud-based integration, advanced security protocols, user-friendly analytics dashboard | Subscription-based |

| Company B | Scalable architecture, customizable interfaces, robust support for legacy systems | One-time purchase |

| Company C | Real-time analytics, extensive support network, proactive maintenance alerts | Hybrid pricing model |

When evaluating suppliers, organizations should consider their specific operational needs, as well as the flexibility offered by each SCADA solution. For example, a company with a diverse range of industrial processes may benefit from a highly customizable interface, while companies focused on rapid deployment might prefer solutions that emphasize cloud compatibility. Engaging in pilot programs and gathering feedback from operators can also provide valuable insights into the usability of different systems before full-scale implementation.

Implementation Steps for IHM SCADA Systems

Implementing an IHM SCADA system necessitates careful planning and execution. Here is a step-by-step guide:

- Needs Assessment: Identify specific operational challenges and objectives to tailor the scope of the system accordingly. This initial stage lays the groundwork for establishing clear goals and expected outcomes from the SCADA implementation.

- Selecting Suppliers: Evaluate potential suppliers based on system capabilities, compatibility, and support services. Conducting market research and comparing multiple vendors can assist in identifying the solution that best aligns with organizational needs.

- System Design: Plan the layout and functionality of the system to ensure seamless integration into existing processes. This design phase should consider not only the technical specifications but also the user experience to facilitate quick adaptation by operators.

- Installation: Deploy the necessary hardware and software components, ensuring all systems are calibrated correctly. Collaboration with suppliers during installation can help mitigate common pitfalls and streamline the setup process.

- Testing and Validation: Conduct thorough testing to confirm the system meets operational criteria and safety standards. This phase includes simulating various scenarios to ensure the system responds appropriately under different conditions.

- Training: Provide ongoing training for operators to maximize the benefits of the system and facilitate troubleshooting. Continuous education should be emphasized, especially as software updates and new features are introduced.

A successful implementation of an IHM SCADA system not only enhances operational efficiency but also fosters a culture of proactive engagement and safety among staff. Organizations should ensure that there is a feedback mechanism in place to continually assess the system's effectiveness and address any emerging challenges in its operation.

FAQs on IHM SCADA Systems

Read below for answers to some common questions about IHM SCADA systems:

- What industries benefit very from IHM SCADA systems?

IHM SCADA is invaluable in sectors like energy, water treatment, manufacturing, and telecommunications for enhanced control and efficiency. Industries such as pharmaceuticals and food and beverage manufacturing also rely on SCADA systems to ensure compliance with strict regulatory requirements and maintain high standards of quality control. - How does IHM SCADA contribute to operational safety?

By providing real-time monitoring and alerts, SCADA systems minimize risks and enable proactive responses to potential hazards. For instance, in chemical processing plants, SCADA can detect unsafe levels of materials and alert operators before a situation escalates into a catastrophic failure. - What are the challenges in implementing an IHM SCADA system?

Key challenges include cost, complexity of integration with existing systems, and ensuring cybersecurity measures are in place. Additionally, garnering buy-in from all stakeholders and training personnel to effectively utilize the new system can often require significant time and resources. - Can IHM SCADA systems integrate with IoT devices?

Yes, modern IHM SCADA systems are often designed to integrate seamlessly with IoT devices, leveraging data from sensors and smart machinery to enhance monitoring and decision-making processes. This integration allows for more granular control and analysis, enabling organizations to maximize output and efficiency. - How can organizations ensure data security in SCADA systems?

Organizations should implement multiple layers of security, including firewalls, encryption strategies, and regular software updates. Additionally, staff training on cybersecurity best practices can play a significant role in reducing vulnerability to external threats.

Conclusion

In conclusion, IHM SCADA systems represent a transformative technology in industrial automation, bridging the gap between human operators and complex processes. These systems not only enhance operational effectiveness but also facilitate better decision-making through real-time data monitoring and analytics. As industries evolve, adhering to the latest technological trends and innovations in IHM SCADA will be crucial for ensuring sustainable growth and competitive advantage. The future of SCADA systems will likely see increased adoption of machine learning and advanced predictive analytics, further refining the capabilities of these essential tools. As businesses continue to navigate the digital landscape, the role of IHM SCADA in ensuring operational excellence and safety cannot be overstated. With thoughtful implementation and continuous improvement, organizations can leverage these systems to create environments that are not only more efficient but also safer for their operators and the ecosystems in which they operate.