Understanding the Zl4460

The Zl4460 is a key component in modern engineering, known for its efficiency and adaptability. This article explores its applications, benefits, and the technological advancements it brings. Designed for a range of industrial uses, the Zl4460 represents a significant innovation, offering enhanced performance in varied conditions.

Introduction to the Zl4460

The Zl4460 is an integral part of modern technological applications, providing robust solutions in various engineering sectors. Its design facilitates advancements by enhancing efficiency and performance in demanding environments. The Zl4460's adaptability to diverse conditions makes it a crucial element in the evolving landscape of industrial technology. With the rapid pace of industry evolution, the Zl4460 represents not only a solution to current challenges but also a beacon for future innovations in various fields.

Technical Specifications and Features

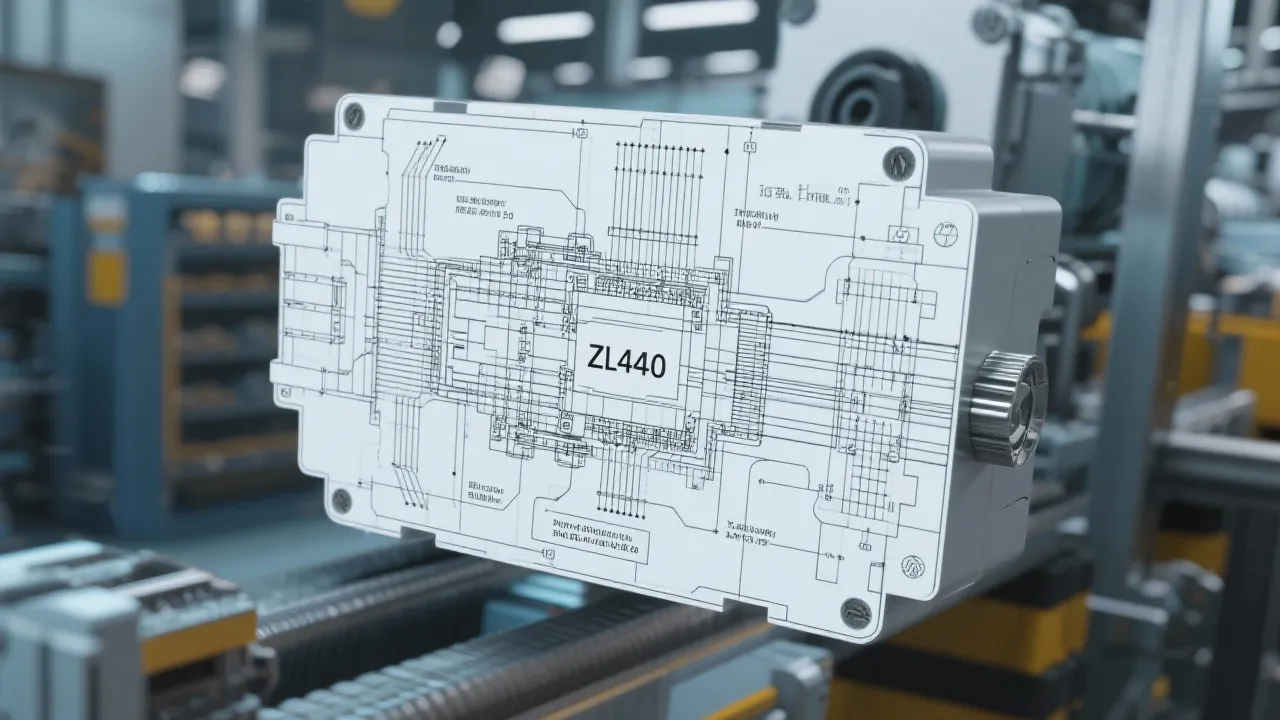

The Zl4460 excels with its high-performance capabilities. It integrates seamlessly into existing systems, allowing for a smooth transition with minimal downtime. The component is lauded for its durability and low maintenance requirements, ensuring cost efficiency over the product's lifespan. Furthermore, its advanced features enable precise control and adaptability, meeting the needs of complex applications. These specifications emphasize the Zl4460’s role as a cornerstone in high-stakes environments, where reliability and precision are paramount.

One notable aspect of its technical specifications includes its temperature resilience, enabling operation in extreme heat and cold, which is critical for sectors like aerospace and outdoor installations. The Zl4460 also features advanced signal processing capabilities, allowing for real-time analysis and adjustments that can significantly enhance operational metrics. This feature empowers users to fine-tune performance to fit specific operational needs, ensuring that the Zl4460 can support various applications ranging from precision manufacturing to critical systems monitoring.

Applications of the Zl4460

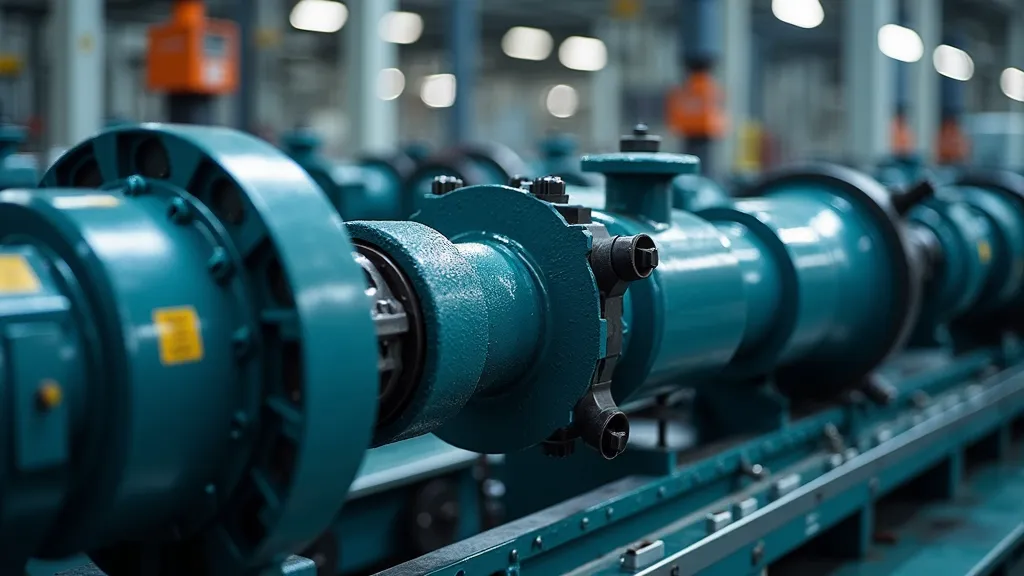

The versatility of the Zl4460 finds its place in various industries, such as automotive, aerospace, and manufacturing plants. As technological advancements progress, the need for components that can enhance efficiency and reduce energy consumption becomes increasingly vital. The automotive sector, for instance, utilizes the Zl4460 in electric vehicles, where energy optimization is a primary focus. By integrating this component, manufacturers can design systems that manage energy distribution more effectively, thereby extending the range and lifespan of electric vehicles.

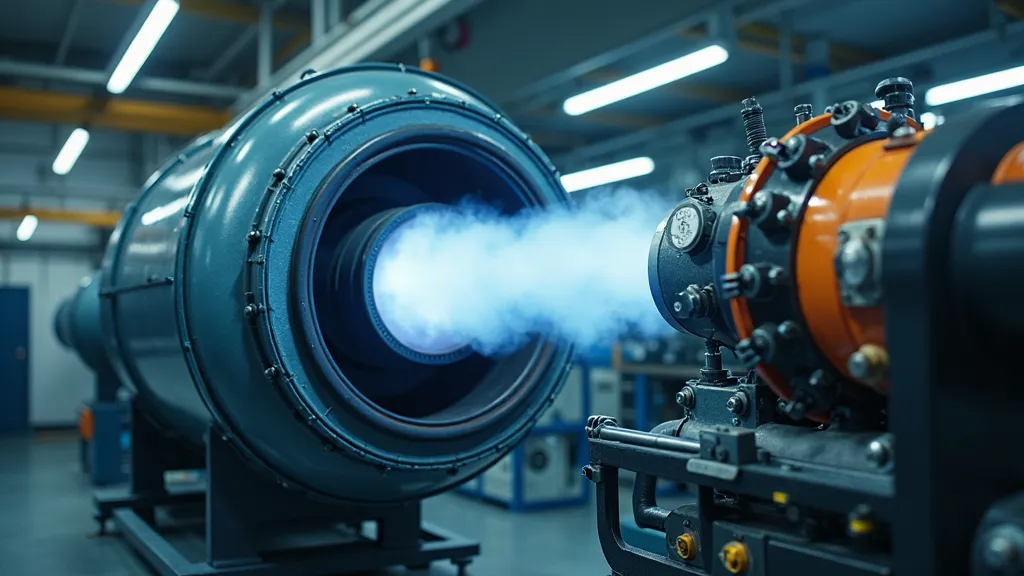

Similarly, in aerospace, the Zl4460 plays a crucial role in avionics where precision and reliability are critical. Components must function flawlessly under a range of conditions, including intense vibration and temperature fluctuations. The Zl4460's ability to operate under stress while providing accurate data and control has made it indispensable in modern aircraft systems.

In manufacturing plants, its implementation can lead to substantial improvements in automation processes. The Zl4460 helps in refining processes such as assembly line operations, where timing and coordination are essential. Its real-time feedback capabilities ensure that issues can be identified and addressed immediately, minimizing downtime and maximizing production efficiency. As industries move towards greener solutions, the Zl4460's design philosophy aligns well with sustainability objectives, promoting an eco-friendly approach without compromising performance.

Implementation and Integration

Integrating the Zl4460 into existing systems requires careful planning and execution. System compatibility and efficiency need to be assessed to maximize the component's full potential. Industry experts emphasize thorough testing and training for personnel to ensure seamless implementation, mitigating potential risks associated with technological transitions. The integration process should begin with a comprehensive audit of current systems to identify areas where the Zl4460 can bring optimization and improve functionality.

Moreover, collaboration between engineers and operational staff is essential during this phase. By facilitating open communication channels, teams can develop tailored integration strategies that focus on the unique needs of their specific applications. Additionally, industry best practices suggest that creating detailed documentation and protocols surrounding the integration process promotes a smoother transition. Training sessions that emphasize the Zl4460's operational capabilities enhance user confidence, which can lead to more effective utilization once integrated.

Post-integration, monitoring the performance of the Zl4460 in real-world applications is crucial for ensuring long-term reliability and effectiveness. Regular assessments can pinpoint any areas needing adjustments, ensuring that the integration remains beneficial over time. This proactive approach not only extends the lifespan of the Zl4460 but also promotes an organizational culture focused on continuous improvement and adaptation in the face of evolving industry challenges.

| Features | Description |

|---|---|

| Performance | High efficiency with a focus on energy conservation. |

| Durability | Long-lasting with minimal upkeep required, suitable for harsh environments. |

| Adaptability | Can be tailored to fit a variety of industrial applications. |

| Control Precision | Facilitates exact operations required in complex systems. |

| Temperature Resistance | Operates efficiently under extreme thermal conditions. |

| Signal Processing | Advanced capabilities for real-time data analysis and adjustments. |

Future Prospects and Developments

The evolution of technology demands continuous innovation, and the Zl4460 exemplifies this trend. Ongoing research and development strive to enhance its capabilities, potentially broadening its applications and efficiency. For example, there is a significant push towards integrating artificial intelligence and machine learning algorithms into the Zl4460's operational framework. These advancements could lead to predictive maintenance capabilities, where the system could analyze trends in its function and predict potential failures before they occur.

Furthermore, the incorporation of IoT technology is on the horizon for the Zl4460, which will enable real-time data sharing across platforms and devices. Such connectivity will not only enhance the performance of individual components but also contribute to the creation of smart factories and infrastructures. Data collected can offer insights into operations, allowing for more strategic decision-making processes aimed at optimizing production and minimizing waste.

As industries increasingly prioritize energy efficiency and sustainable practices, the Zl4460 can play a crucial part in driving this transition. Future iterations may focus on developing lighter and more efficient materials, reducing the overall environmental footprint of the component itself. Additionally, advances in manufacturing processes could lead to more sustainable production methods for the Zl4460, which would further align with global environmental standards and regulations.

Moreover, collaboration between technology developers, industry leaders, and researchers will play a vital role in shaping the future trajectory of the Zl4460. By fostering partnerships that focus on research, development, and practical application, the Zl4460 can continue to stand at the forefront of technological innovation, leading various sectors toward a smarter and more sustainable future.

FAQs

Q: What makes the Zl4460 stand out in its field?

A: The Zl4460 distinguishes itself with its robust performance, energy efficiency, and adaptability across various industries, making it a vital component in modern engineering.

Q: How does the Zl4460 contribute to sustainability?

A: Its design focuses on reducing energy consumption and waste, aligning with eco-friendly practices and sustainable industrial operations. The Zl4460 promotes a greener approach by optimizing performance in energy-heavy applications, thereby supporting overall sustainability goals.

Q: Can the Zl4460 be integrated with older systems?

A: Yes, the Zl4460 is designed for compatibility with existing systems, but careful planning and testing are recommended to ensure optimal integration. This process may include software updates or hardware modifications to accommodate the Zl4460’s advanced features, ensuring that legacy systems can tap into its capabilities without significant overhauls.

Q: What industries benefit most from the Zl4460?

A: Industries such as automotive, aerospace, manufacturing, and energy management are among those that can significantly benefit from the Zl4460. Each of these sectors leverages the Zl4460's capabilities to enhance performance metrics, improve operational efficiency, and contribute toward sustainable practices.

Q: Are there any particular challenges in implementing the Zl4460?

A: While the Zl4460 is designed for easy integration, challenges may arise related to system compatibility, training personnel, and ensuring thorough testing. Addressing these challenges early in the process through structured planning and communication can mitigate risks and facilitate a more effective integration experience.

Q: How does continuous development impact the usability of the Zl4460?

A: Continuous development ensures that the Zl4460 remains at the cutting edge of technology. As enhancements and new features are introduced, users can expect improved performance and capabilities, making it essential for industries to stay informed about updates and upgrades for optimal utilization of the component.