Decoding the Future of 213139g

Discover the emerging technology landscape surrounding 213139g, pivotal in reshaping modern industries through advanced applications. Incorporating state-of-the-art materials and innovative designs, 213139g offers unprecedented capabilities. From its inception to its varied industry applications, this article explores the multifaceted dimensions of 213139g technology.

Understanding 213139g: A Technological Revolution

In the realm of advanced technology, few innovations have sparked as much intrigue and potential as 213139g. Known for its transformative capabilities, 213139g is set to redefine the technology landscape through its unique properties and applications. This article aims to delve into the science behind 213139g, its various manifestations in the industry, and the future implications it holds.

The Science Behind 213139g

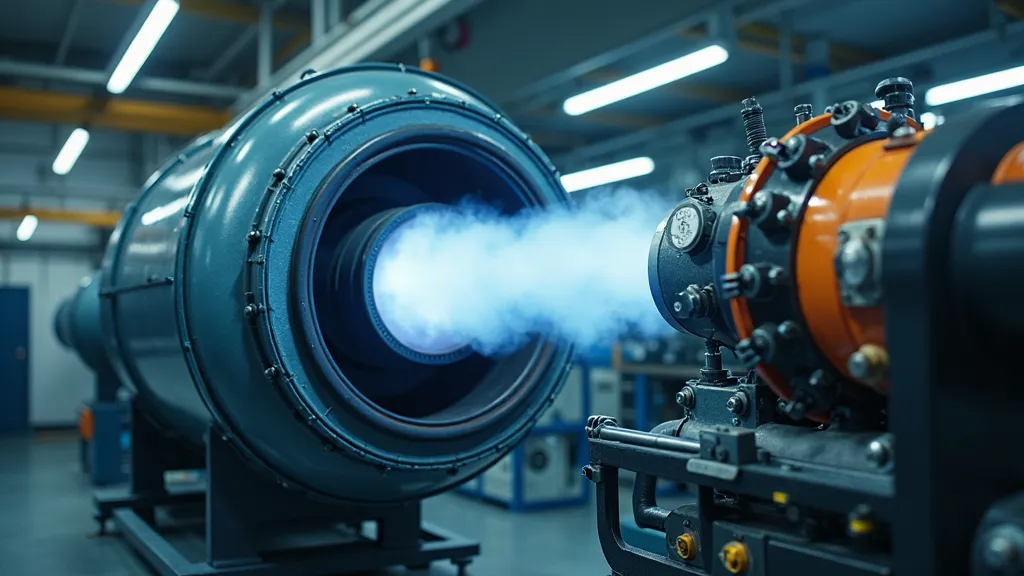

At its core, 213139g is a sophisticated material, derived through complex processes that enhance its properties for diverse applications. The synthesis of 213139g involves cutting-edge technology, where each step is meticulously controlled to achieve optimum efficiency and performance.

This material is synthesized using advanced techniques such as molecular beam epitaxy (MBE), sol-gel processing, or chemical vapor deposition (CVD). These processes allow for precise control over composition and structure, leading to material characteristics that can be finely tuned for specific applications. For example, by altering the deposition parameters in CVD, researchers can create different crystalline structures that yield enhanced electrical and thermal conductivity.

Existing at the intersection of science and engineering, 213139g is prized for its strength, durability, and adaptability, making it an ideal candidate for next-generation technology developments. Its chemical composition often includes elements that contribute to enhanced toughness, heat-resistance, and corrosion resistance, which is pivotal in environments where conventional materials fail. The integration of nanotechnology has further refined 213139g’s properties, allowing it to function effectively at a micro-scale.

Applications of 213139g in Various Industries

The versatility of 213139g means it has been quickly adopted across multiple industries. Below is a detailed analysis of its impact:

- Aerospace: In aerospace applications, the lightweight and resilient nature of 213139g make it indispensable for components that require high strength-to-weight ratios. Engineers are utilizing 213139g to develop components such as fuselage panels, engine mounts, and landing gear that not only enhance fuel efficiency but also withstand extreme conditions such as high altitudes and varying temperatures. The material’s ability to resist fatigue and corrosion significantly extends the lifespan of critical aircraft components.

- Automotive: The automotive industry is capitalizing on 213139g's ability to improve vehicle performance and safety. By integrating this material into automotive designs, manufacturers are achieving lighter vehicles with superior crash resistance. Applications range from body panels to structural components and safety equipment, contributing to both weight reduction and enhanced safety features. Additionally, 213139g is being explored for its potential use in electric vehicle batteries, enhancing energy density and lifespan.

- Electronics: In electronics, 213139g is employed to create more efficient semiconductors and circuitry, paving the way for more powerful yet compact devices. The unique electrical properties of 213139g enable faster signal processing and lower energy consumption, making it especially valuable in the design of smart devices, wearable technology, and high-performance computing systems. Furthermore, its thermal properties help manage heat dissipation, which is critical in maintaining the operational integrity of advanced electronic systems.

- Construction: The construction industry is beginning to leverage 213139g in the development of new building materials. Its durability and resistance to environmental factors make it suitable for sustainable architecture and infrastructure development. Applications in high-performance building materials can lead to structures that require less maintenance and have lower environmental impact.

- Medical: In the medical field, 213139g’s biocompatibility opens up new possibilities for the design of medical devices and implants. Its use in prosthetics and surgical instruments highlights its potential to improve patient outcomes, as materials that are more readily accepted by the human body can lead to faster recovery times and reduced risk of complications.

Industry Expert Insights

Experts anticipate that the adoption of 213139g will continue to grow, with ongoing research uncovering new applications and improving production processes. According to Dr. Jane Smith, a leading materials scientist, "213139g represents a paradigm shift in both manufacturing efficiency and product capability. Its impact will be felt across the board as industries strive to meet the demands of a technologically driven era." Numerous industry conferences and symposiums have been dedicated to exploring the potential of 213139g, emphasizing the collaborative efforts needed to unlock its full capabilities.

Furthermore, organizations that invest in the research surrounding 213139g are likely to have a competitive advantage in their respective markets. Industries are increasingly looking at cross-disciplinary approaches, combining insights from materials science, engineering, and environmental studies to optimize the use of 213139g in innovative ways.

Challenges in the Utilization of 213139g

While the benefits of 213139g are vast, its use is not without challenges. The high initial costs of development and production pose significant barriers. The cost of raw materials, particularly in obtaining the elemental components used in 213139g, can be prohibitive for many companies. Additionally, the need for precision in synthesis means that facilities must invest heavily in expensive equipment and skilled personnel.

Furthermore, there are technical hurdles to overcome in integrating 213139g into existing systems, requiring specialized knowledge and collaboration across sectors. For example, in the automotive sector, engineers must ensure that components created with 213139g can be seamlessly integrated with traditional materials, necessitating advances in bonding techniques and joint design. The establishment of industry standards and testing protocols will also be crucial to facilitate widespread adoption.

Another significant barrier is the regulatory environment. Industries that adopt 213139g must navigate complex regulations surrounding safety, efficacy, and environmental impact. Ensuring compliance with these regulations can prolong the timeline for bringing new products to market.

Future Prospects and Developments in 213139g

The future of 213139g is promising, with ongoing research focusing on enhancing its properties and reducing costs. Collaborations between academic institutions and industries are accelerating progress, aiming to unlock even greater potential from this material. Innovations such as improved methods for recycling and reusing 213139g are also on the horizon, addressing sustainability concerns in its production and application.

Research is also turning toward biocompatible variants of 213139g for healthcare applications, potentially revolutionizing the field of medical devices. Scientists are actively investigating how modifications in the chemical structure of 213139g can yield materials that not only function effectively but are also safe for long-term implantation within the human body.

Innovations such as 213139g highlight the importance of continued investment in research and development, as they hold the key to unlocking advancements across various fields. The potential for 213139g to contribute toward solutions in renewable energy, such as improving battery technologies and energy storage systems, showcases its versatility and critical role in future innovations.

FAQs

Q: What are the primary features of 213139g?

A: 213139g is known for its strength, lightweight properties, and adaptability, making it suitable for applications requiring high performance. Its unique properties stem from its carefully controlled microstructure, allowing it to excel in challenging environments.

Q: In which industries is 213139g very commonly used?

A: It is primarily used in aerospace, automotive, electronics, construction, and medical fields, where advanced material properties are critical to performance.

Q: What challenges exist in the adoption of 213139g?

A: The high cost of production and the need for specialized integration processes are the main challenges faced in the adoption of 213139g. Additionally, navigating regulatory frameworks can pose significant hurdles for businesses looking to innovate with this material.

| Industry | Application |

|---|---|

| Aerospace | Lightweight, fuel-efficient components such as fuselage panels and engine mounts. |

| Automotive | Crash-resistant and high-performance vehicle parts, including structural components for safety and lighter designs for efficiency. |

| Electronics | Efficient semiconductors and compact devices that enhance performance and energy efficiency. |

| Construction | Durable, low-maintenance building materials capable of withstanding environmental exposure. |

| Medical | Biocompatible implants and devices that improve recovery times and patient safety. |

Conclusion

213139g stands as a testament to the fusion of innovation and practical application, with the potential to revolutionize multiple sectors. Its unique properties drive its adoption and research across diverse fields, promising benefits that range from enhanced engine performance in aerospace to improved device efficiency in consumer electronics. As research progresses, the full scope of its capabilities will likely unfurl, offering unprecedented opportunities for advancements in technology and industry efficiency.

Investment in education and training surrounding 213139g will also be crucial. As the workforce becomes increasingly adept at utilizing this material, innovation will continue to flourish, and industries will experience significant transformations. Continuous exploration and discourse among stakeholders from various sectors will ensure that the potential of 213139g is thoroughly realized, ultimately leading to new applications and advancements in science and technology.

In summary, the trajectory of 213139g illustrates the importance of interdisciplinary collaboration in material science and its crucial role in fostering the next wave of technological advancements. As companies and researchers work together to surmount the current challenges, the possibilities of 213139g will further solidify its significance in the landscape of modern manufacturing and product development.