Emflex: Revolutionizing Modern Manufacturing

Emflex stands at the forefront of advanced manufacturing solutions, offering innovative approaches to enhance efficiency and precision in production processes. As the manufacturing industry evolves, Emflex emerges as a leader in integrating adaptive technologies to meet modern demands, ensuring high-quality output and operational sustainability.

Introduction to Emflex

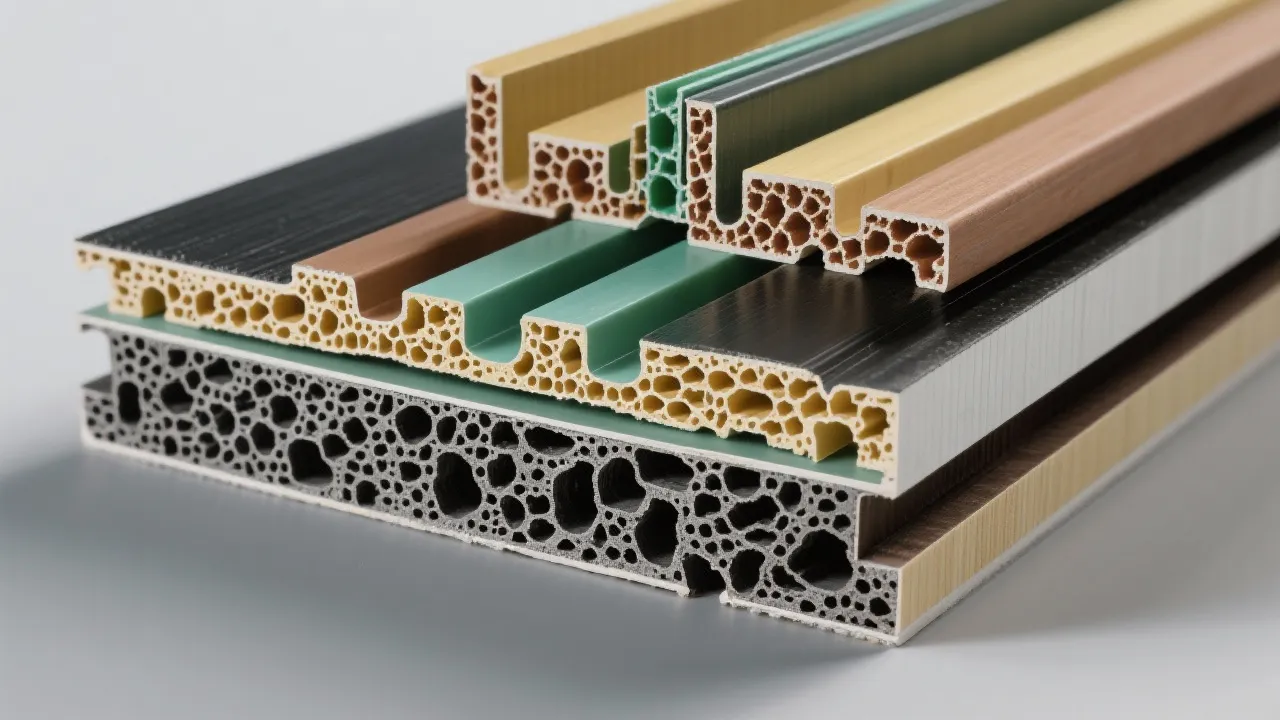

In today's rapidly evolving industrial landscape, Emflex presents cutting-edge solutions that streamline manufacturing processes. By integrating adaptive technologies, Emflex enhances efficiency, precision, and sustainability in production. Its versatility makes it a vital asset across various sectors, from automotive to electronics. As manufacturers face increasing pressures to optimize output while minimizing costs, Emflex has emerged as a beacon of innovation. This platform promotes more than just profitability; it also emphasizes responsible resource usage and environmental consciousness, which are essential considerations for modern businesses.

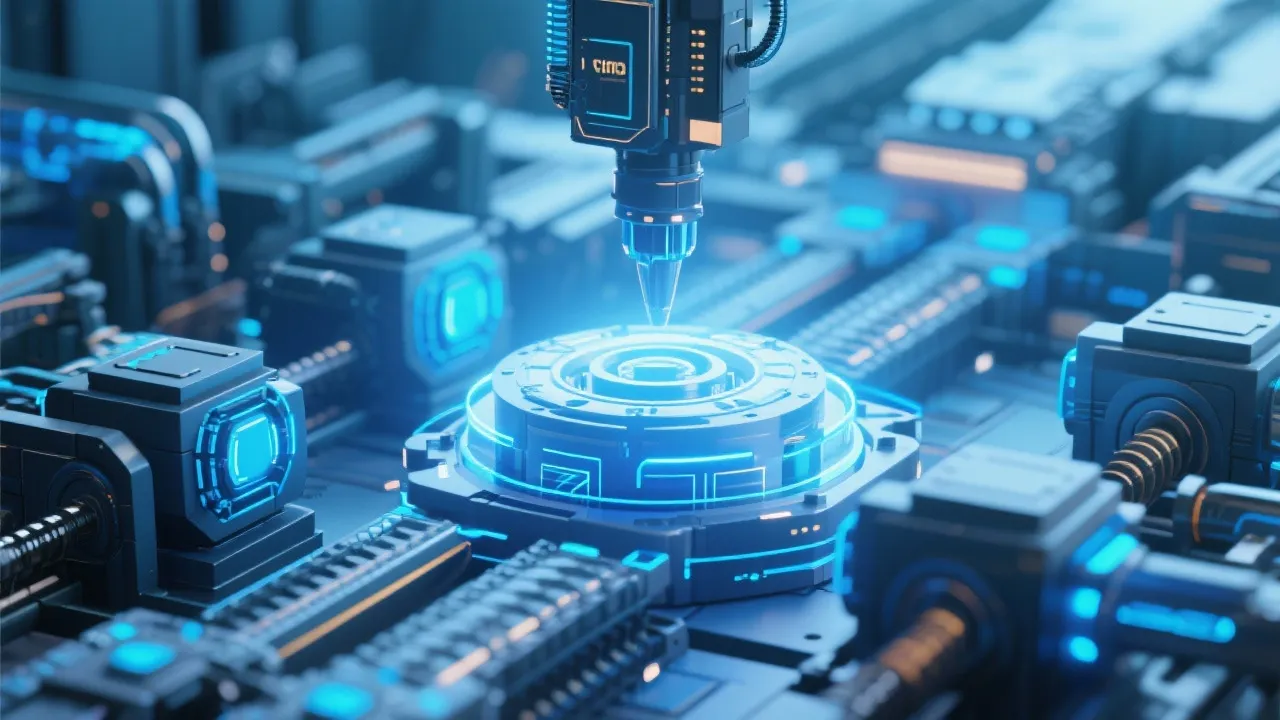

Emflex: The Core of Modern Manufacturing Innovation

At the heart of Emflex's success is its ability to seamlessly blend advanced technologies with practical applications. This includes adopting automation, artificial intelligence, and real-time data analysis, which revolutionize traditional manufacturing methods. Emflex ensures high-quality product output, reducing production time and minimizing resource consumption significantly. Moreover, the integration of machine learning algorithms allows systems to continuously improve their performance based on historical data and emerging trends. This progressive approach enables manufacturers to stay ahead of their competitors and adapt to shifting consumer preferences.

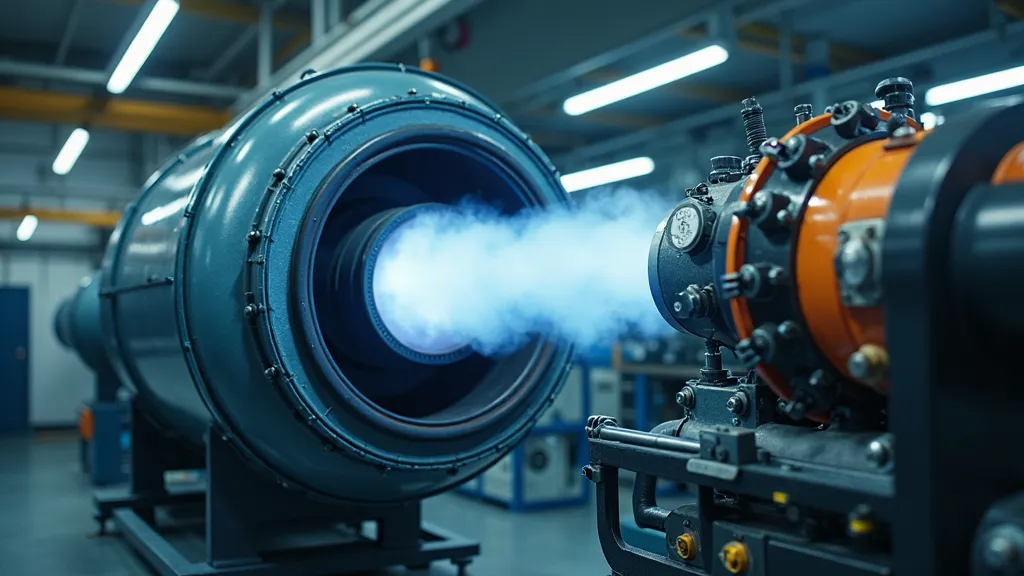

Industry Applications of Emflex

Automotive Industry: Emflex improves automotive manufacturing by enabling precise component assembly, ensuring uniformity, and enhancing safety standards. The technology helps manufacturers streamline assembly lines, reduce waste, and create products that comply with stringent safety regulations. Additionally, the use of Emflex facilitates the production of electric and hybrid vehicles, which are becoming increasingly popular and necessary amid the global push for sustainability.

Electronics Manufacturing: The integration of Emflex in electronics allows for intricate circuitry and component miniaturization, meeting the industry's demand for advanced consumer gadgets and electronic devices. These innovations support the production of high-performance smartphones, tablets, and smart home devices that are small in size but powerful in capability. The ability to manufacture these products efficiently and sustainably positions companies for growth in a competitive market.

Benefits of Implementing Emflex

Employing Emflex in production facilities presents numerous advantages, including:

- Enhanced Efficiency: Automation and AI reduce manual labor, decrease error rates, and increase output speed. With processes that once required extensive human input now being handled by AI systems, workers can focus on tasks that require more creativity and critical thinking.

- Sustainability: Emflex technologies support environmentally friendly processes, utilizing resources responsibly and reducing waste. This commitment to sustainability not only reflects positively on the brand but also helps ensure compliance with growing regulatory demands around environmental impact.

- Adaptive Flexibility: Its adaptive systems allow quick responses to market changes and consumer demands, aiding business growth. By swiftly reallocating resources and manufacturing capabilities, companies can capitalize on emerging trends and pivot when necessary, thereby gaining a competitive edge.

Comprehensive Expert Insights

Drawing insights from industry reports, Emflex has been hailed as a transformative tool in manufacturing. According to a recent study by the Manufacturing Technology Association, facilities using Emflex reported a 30% uptick in overall productivity and a 20% reduction in production costs within the first year of implementation. Experts note that this technology fosters an environment of continuous improvement, encouraging firms to innovate processes and approaches as market demands evolve. As Emflex becomes synonymous with efficiency, companies that adopt this technology are likely to set themselves apart in their respective industries.

Table: Comparing Traditional Manufacturing with Emflex Technology

| Aspect | Traditional Manufacturing | Emflex Technology |

|---|---|---|

| Efficiency | Moderate, reliant on manual processes | High, due to automation and AI |

| Sustainability | Resource-heavy, higher waste production | Resource-efficient, minimal waste |

| Flexibility | Limited, slow adaptation to changes | Highly flexible, quick adaptation |

FAQ

What industries benefit greatly from Emflex?

The automotive, electronics, aerospace, and consumer goods industries benefit greatly, thanks to Emflex's enhanced precision and efficiency. Additionally, sectors such as pharmaceuticals and food production are finding innovative applications of Emflex that enhance quality control and reduce waste in production lines.

How quickly can a facility transition to Emflex?

The transition speed varies by facility size, but typically, a structured implementation plan allows for seamless integration within months. Factors influencing this timeline include the existing infrastructure, employee training programs, and the complexity of the production processes being automated.

Is Emflex cost-effective for all businesses?

While initial investments might be substantial, the subsequent savings in production costs and elevated efficiency often justify the expenditure. In many cases, the return on investment may be realized within the first year, making it a savvy choice for forward-thinking organizations.

Can Emflex technology be customized?

Yes, one of the significant advantages of Emflex is its adaptability. Organizations can tailor the technology to fit their specific production needs while aligning with their business goals, thus optimizing their operational efficiency.

What training is necessary for employees to use Emflex?

Training programs are crucial for ensuring that workers understand how to operate Emflex effectively. Typically, manufacturers will implement a robust training regimen that includes both theoretical and practical components, allowing employees to familiarize themselves with the technology and its applications.

Conclusion

Emflex represents a milestone in adaptive manufacturing technologies, bridging the gap between traditional practices and futuristic demands. Its widespread application and potential for significant cost savings ensure that Emflex remains indispensable in the ongoing evolution of industrial processes. With a focus on efficiency, sustainability, and adaptability, Emflex not only meets the current needs of the market but also paves the way for future innovations. As industries continue to confront the challenges of globalization, technological advancement, and environmental pressures, Emflex stands out as a frontrunner, helping organizations not only survive but thrive in a complex and rapidly changing environment. It is clear that businesses investing in Emflex technology are not just enhancing their production capabilities—they are also setting themselves on a trajectory toward sustained success and market leadership.

The Future of Emflex and Its Impact on Industry

Looking ahead, Emflex technology is poised to play an even more significant role in shaping the manufacturing sector. As the Internet of Things (IoT) continues to expand its reach, Emflex will likely integrate more deeply with smart devices and interconnected systems. This will enable real-time monitoring and control of production processes, further driving efficiency and quality standards across industries.

Moreover, the emergence of Industry 4.0, characterized by the integration of digital technologies, data analytics, and automation, presents a profound opportunity for Emflex. By participating in this transformative phase of manufacturing, Emflex can help businesses adapt to the rapid changes dictated by technological advancements, supply chain challenges, and evolving customer expectations.

As companies navigate the complexities of a post-pandemic economy, those that embrace Emflex technology will be better equipped to pivot quickly in response to market fluctuations and consumer demands. The ongoing need for agility in production will likely spur further innovations within the Emflex framework, ensuring its relevance for years to come.

Real-world Success Stories of Emflex Implementation

To illustrate the real-world applications and benefits of the Emflex system, several companies have successfully incorporated this technology into their manufacturing processes, achieving remarkable results.

Case Study: An Automotive Manufacturer

One leading automotive manufacturer faced challenges in maintaining production efficiency while adhering to safety standards. By integrating Emflex technology, they automated their assembly line. Within six months, the manufacturer reported a 40% decrease in assembly time and improved adherence to safety protocols due to reduced human error. This swift implementation not only enhanced their production capacity but also allowed them to launch new models more rapidly in response to market trends.

Case Study: An Electronics Company

An electronics company, known for its consumer gadgets, integrated Emflex for its production of sophisticated devices. Before adoption, the company struggled with high defect rates in its products. After implementing Emflex's precise tooling and real-time quality monitoring systems, they reduced their defect rates to under 1%. This notable improvement not only enhanced customer satisfaction but also strengthened their position in a fiercely competitive market.

Case Study: A Food Production Facility

One food production facility struggled with compliance issues related to cleanliness and operational consistency. By utilizing Emflex, they established stringent monitoring systems that ensured hygiene standards were met throughout the production cycle. The facility not only improved its product quality and decreased waste but also successfully navigated regulatory requirements without significant operational disruptions.

Conclusion: Emflex as a Catalyst for Future Innovation

As the manufacturing industry continues to evolve at an unprecedented pace, Emflex stands out as a crucial catalyst for innovation and efficiency. The technology's ability to integrate seamlessly with existing systems while offering scalability and adaptability positions it as an essential tool for businesses looking to thrive in this competitive landscape. Furthermore, as sustainability becomes increasingly paramount, Emflex enables companies to produce goods responsibly and efficiently, contributing to their corporate social responsibilities.

In conclusion, Emflex is not just a solution for the manufacturing challenges of today; it is a foundational technology that will influence the future trajectory of the industry. By adopting Emflex, organizations are not only investing in their operational capabilities but also their long-term viability in an ever-changing global market landscape.