Unveiling the Future with Emflex

Emflex is revolutionizing technology with its innovative applications in various sectors, driving efficiency and performance. Emflex represents a groundbreaking advancement in material science and engineering, offering versatile solutions across multiple industries. As industries evolve, Emflex introduces new methods for enhancing sustainability, reducing costs, and optimizing processes. This guide explores the impact of Emflex and its transformative potential.

Introducing Emflex: A Technological Marvel

Emflex, a defining innovation in material science, is attracting attention across diverse industries for its versatility and unique properties. As the synergy between technology and material innovation deepens, Emflex stands out as a pioneer in advancing efficiency, sustainability, and cost-effectiveness. The development of Emflex has not only transformed the landscapes of various sectors but also catalyzed a paradigm shift in how materials can be harnessed to meet the rigorous demands of modern applications.

The Emflex Advantage

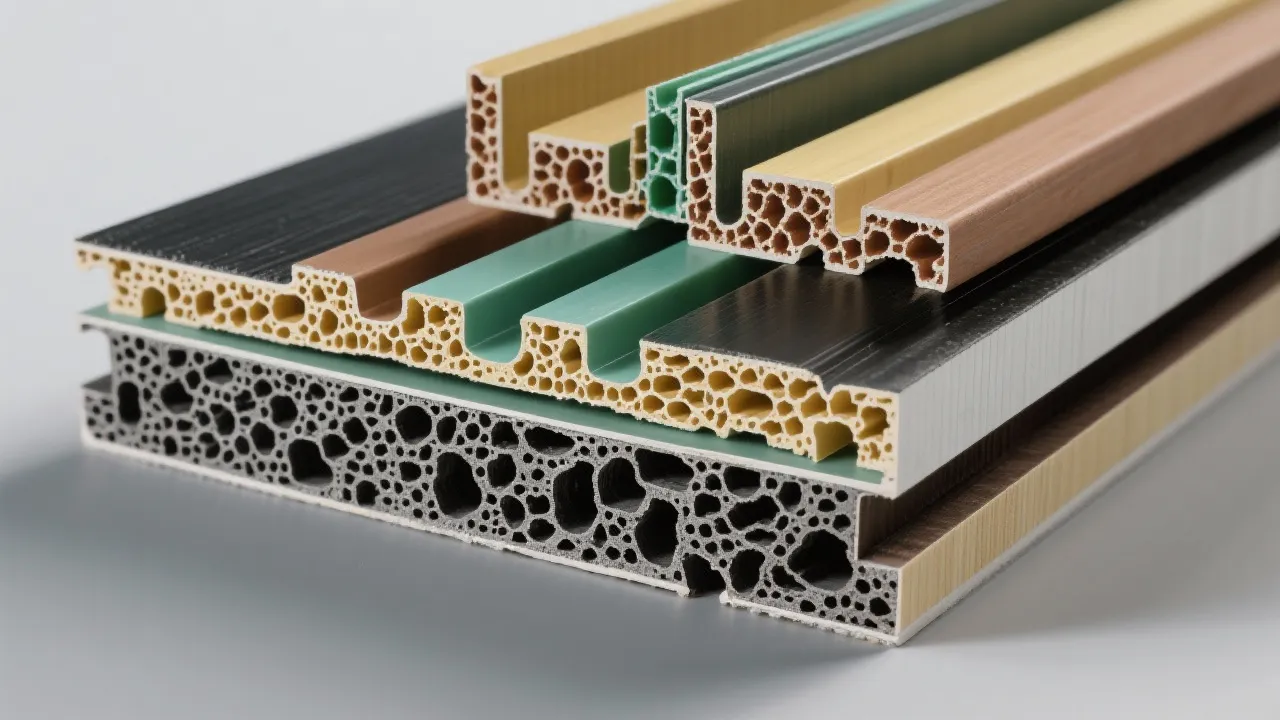

Recognized for its lightweight yet robust composition, Emflex is redefining standards in manufacturing, construction, and transportation. Its application has resulted in unprecedented improvements in product durability and operational cost reductions, showcasing its adaptability and strategic potential. The advantages offered by Emflex extend beyond physical properties to include significant economic and environmental benefits that make it a game-changer in the industrial arena.

- Resilience: Emflex's durability makes it ideal for high-stress environments, offering longevity and reduced maintenance. Its structure allows for resistance against extreme temperatures and corrosive elements, making it suitable for outdoor applications where traditional materials may fail.

- Lightweight Composition: Despite its strength, Emflex maintains a lightweight profile, critical for industries like aviation and automotive where weight impacts efficiency. This quality not only aids in reducing fuel consumption but also enhances the overall performance and agility of vehicles and machinery.

- Environmental Impact: As sustainability becomes a priority, Emflex's innovation aids in lowering carbon footprints through material efficiency and reduced waste. The manufacturing processes involved in creating Emflex are designed to minimize environmental harm, aligning with global goals aimed at reducing material waste and promoting green technologies.

Sector-Specific Applications of Emflex

Across industries, Emflex is disrupting conventional methods with its multifunctional capabilities. Below, we explore how Emflex is making waves in key sectors:

Manufacturing and Production

In manufacturing, Emflex is utilized to produce components that are not only durable but also cost-efficient, shortening production cycles and improving profit margins. The compatibility of Emflex with automated systems further enhances efficiency, paving the way for state-of-the-art manufacturing processes. For instance, the lightweight nature of Emflex allows it to be integrated into robotic systems where precision and speed are crucial, ultimately leading to innovations in automated assembly lines.

Moreover, companies adopting Emflex are witnessing a significant reduction in raw material costs, as its strength allows for thinner, lighter components without compromising on quality. This optimization leads to enhanced output and flexibility, enabling manufacturers to adjust rapidly to market demands.

Construction and Infrastructure

For the construction industry, the usage of Emflex addresses both practical and environmental concerns. Its resistance to wear and weather ensures longevity in infrastructure projects, while its eco-friendliness supports sustainable building initiatives. When integrated into structures, Emflex reduces the overall weight, which subsequently influences the calculations for foundations and structural supports, leading to major cost savings in materials and labor.

Innovative building designs are now made possible through Emflex, showcasing not only modern aesthetics but also improved functionality. Additionally, the rapid construction techniques enabled by Emflex allow builders to meet deadlines more efficiently while adhering to stringent safety regulations.

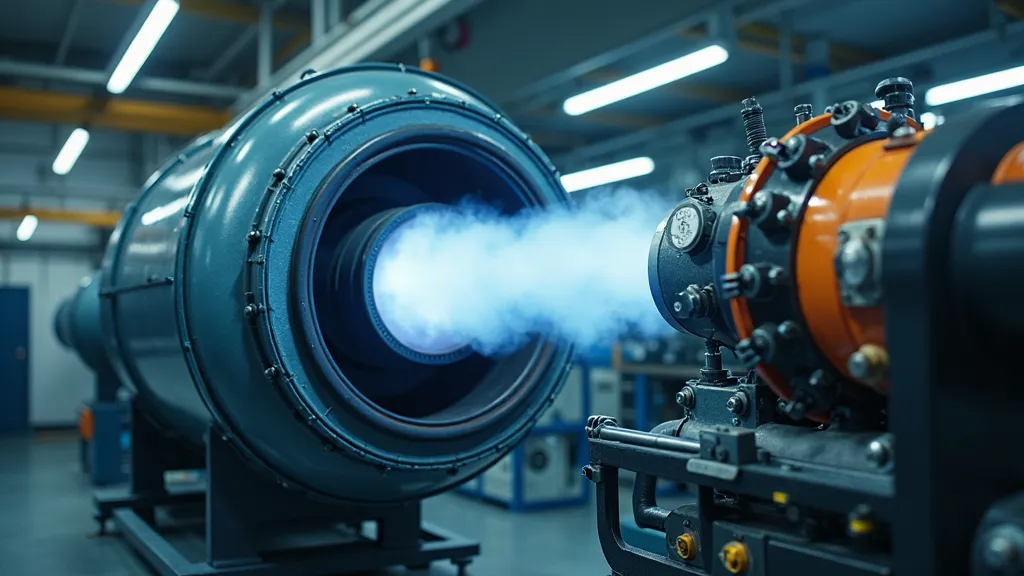

Transportation and Aviation

The demand for lightweight yet strong materials in transportation aligns perfectly with Emflex's characteristics. It supports vehicle innovation by enhancing fuel efficiency and safety standards, crucial factors in contemporary transportation design. By replacing heavier materials with Emflex in automotive manufacturing, companies are able to produce vehicles that achieve higher miles per gallon, significantly lowering operational costs over the lifetime of the vehicle.

Furthermore, in the aviation sector, where weight directly affects fuel consumption, the implementation of Emflex in aircraft construction is a revolutionary step forward. Aircraft manufacturers are now capable of reducing the weight of critical components without sacrificing safety or performance, thereby contributing to substantial reductions in operating costs for airlines.

Why Emflex Matters: An Industry Expert's View

Industry leaders are increasingly recognizing the role of Emflex as a cornerstone of next-generation technology. Experts suggest that its contributions could become pivotal in setting benchmarks for future advancements. As the pressure to innovate intensifies, Emflex provides a reliable and sustainable answer to the challenges faced by industries that are continuously seeking more efficient materials.

Several leading figures in material science have hailed Emflex as a potential key player in the global transition towards smarter, greener technologies. Its multifaceted applications are expected to pave the way for new standards that prioritize not only performance and efficiency but also environmental responsibility."

Comparative Analysis of Emflex Features

| Feature | Standard Material | Emflex |

|---|---|---|

| Weight | Heavier | Lightweight |

| Durability | Moderate | High |

| Environmental Impact | High waste | Low waste |

| Cost Efficiency | Variable | High |

| Production Speed | Slow | Fast |

| Applications | Limited | Diverse |

FAQs on Emflex

Below are some frequently asked questions about Emflex, shedding light on its applications and future potential:

- What industries benefit the most from Emflex? Industries such as aviation, construction, automotive, and manufacturing find significant advantages due to Emflex's properties. Its adaptability makes it suitable for various applications from consumer products to large-scale infrastructures.

- How does Emflex promote sustainability? Emflex reduces waste and energy consumption during production, aligning with sustainable practices across industries. Its recyclability also contributes to a circular economy, enabling manufacturers to minimize waste at the end of a product's life cycle.

- Is Emflex cost-effective? Yes, Emflex often translates to lower operational costs due to reduced maintenance needs and improved production efficiency. Its intrinsic qualities allow for less frequent replacements, directly affecting the bottom line of businesses that incorporate it into their processes.

- Can Emflex be used in critical applications? Absolutely! Emflex's high durability and lightweight nature make it ideal for critical applications such as aerospace components, structural parts in buildings, and automotive safety features, where reliability is paramount.

- What is the future of Emflex in the materials market? The future appears bright for Emflex as more industries seek innovative materials that meet both economic and environmental standards. Continuous research and development are expected to unlock even more applications and improve existing properties, positioning Emflex as a leader in the materials market.

Conclusion: The Path Ahead for Emflex

As industries continue to evolve and prioritize innovation, Emflex's role as a transformative material becomes increasingly prominent. Its impact on sustainability, efficiency, and cost-effectiveness reinforces its importance in the modern technological landscape. As companies seek cutting-edge solutions to remain competitive, incorporating Emflex into their processes could prove to be an advantageous investment. The potential of Emflex extends beyond merely enhancing individual sectors; it symbolizes a movement towards a more streamlined, responsible approach in material usage, which is vital for future technological advancements.

Looking ahead, we can anticipate further enhancements to Emflex's properties, possibly making it even more resilient, versatile, and eco-friendly. Collaborations between material scientists, engineers, and industry leaders will likely spur the creation of innovative composite materials that integrate Emflex technology, paving the way for breakthroughs that redefine what's possible in manufacturing and construction.

In a world where environmental concerns are paramount, Emflex is positioned to lead the charge towards sustainable practices that do not compromise the convenience and efficacy that modern life demands. The continued adoption of Emflex in various sectors will play a crucial role in inspiring future generations to embrace sustainable technologies, ultimately carving a path towards ecological resilience among industries worldwide.