Understanding IHm Scada Systems

This article delves into the intricacies of IHm Scada systems, focusing on their crucial role in industrial automation. Scada, or Supervisory Control and Data Acquisition, is integral for monitoring and controlling industrial processes. In exploring IHm Scada's applications, we highlight its impact on efficiency, cost-effectiveness, and system safety, providing a comprehensive understanding from an expert's perspective.

Introduction to IHm Scada Systems

In the realm of industrial automation, IHm Scada systems represent a vital component in the seamless functioning of manufacturing and process industries. These systems enable real-time monitoring and control, thereby ensuring operational efficiency and safety. Understanding the role of IHm Scada involves delving into its purpose, functionality, and advantages within various industrial settings. As industries continue to evolve and adapt to new technologies, the importance of using advanced Scada systems cannot be overstated. The demand for efficiency and productivity forms the backdrop against which IHm Scada systems are deployed, not just as a tool but as a strategic asset for organizations aiming to maintain a competitive edge in a fast-paced market.

The Role of IHm Scada in Industrial Automation

IHm Scada systems are designed for the comprehensive supervision of industrial processes, ranging from data acquisition to the automated control of equipment and machinery. They play a crucial role in linking software and hardware components, providing users with an intuitive interface to manage operations efficiently. By leveraging real-time data, these systems allow operators to make informed decisions, respond to alarms promptly, and maintain optimal workflow within facilities. The integration of modern technologies such as the Internet of Things (IoT) and artificial intelligence (AI) has further enhanced the capabilities of IHm Scada systems, enabling predictive maintenance and more sophisticated data analysis.

Moreover, as industries increasingly adopt sustainable practices, IHm Scada systems contribute by optimizing resource consumption and improving energy efficiency. In sectors like energy management, for example, these systems can help in monitoring power usage and reducing waste, thus facilitating greener operations. Ultimately, IHm Scada systems not only support day-to-day operations but also pave the way for long-term strategic planning in line with contemporary industrial demands.

Components and Functionality

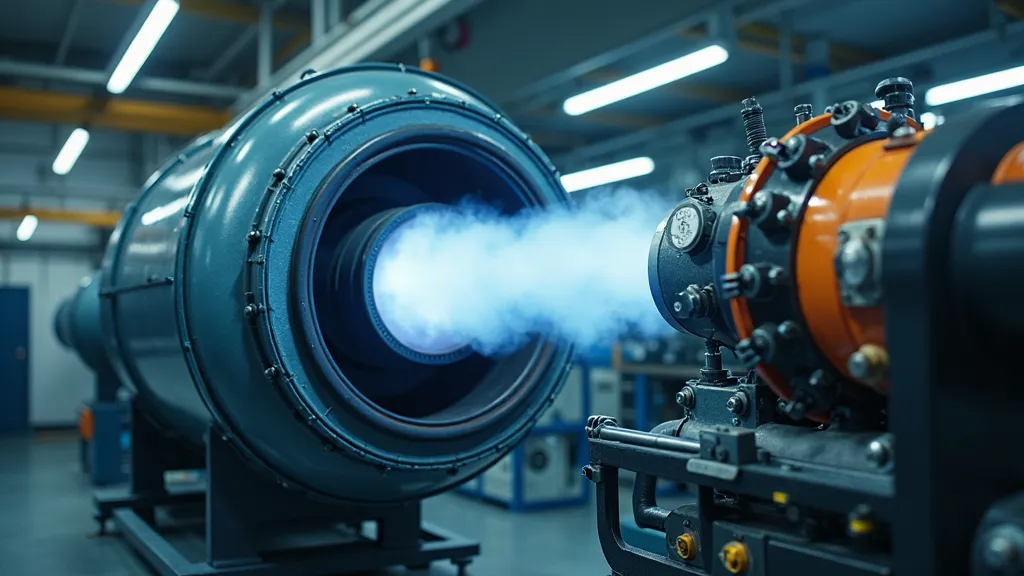

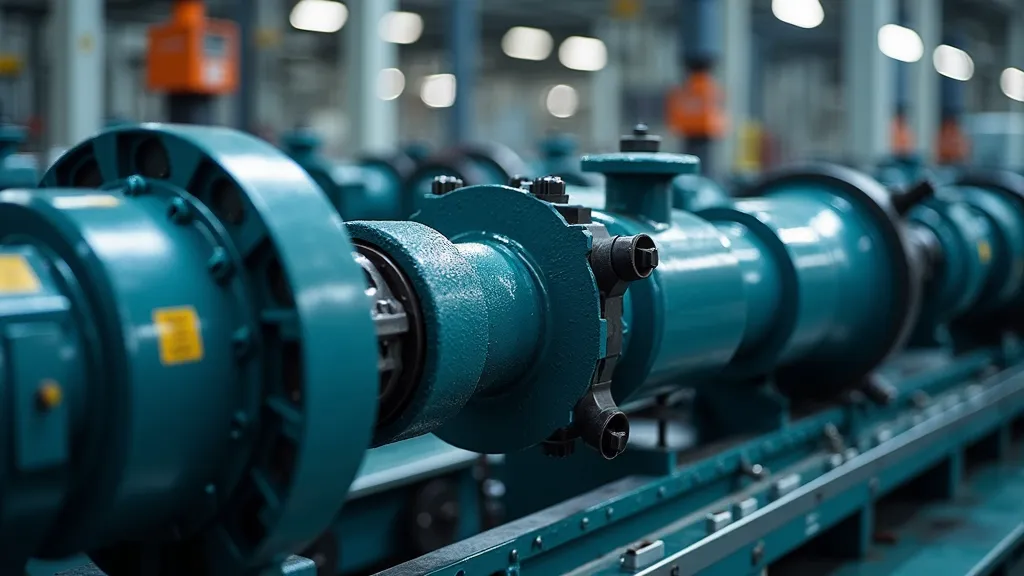

An IHm Scada system is typically comprised of several integral components: sensors and actuators gather data, Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs) process this data, communication networks transmit it, and central computers store and display information through Human Machine Interfaces (HMIs). This architecture enables precise process visualization and control, ensuring that operators can effectively supervise complex industrial tasks.

Each component plays a distinct role in the ecosystem of IHm Scada systems. The sensors, for instance, are responsible for taking physical measurements, such as temperature, pressure, or flow rate. These readings are then transmitted to RTUs or PLCs, where data processing occurs. PLCs, in particular, integrate both hardware and software to perform logical operations that control the machinery accordingly. On the communication front, several protocols such as Modbus, DNP3, and OPC UA ensure that data is transmitted securely and promptly across devices. This communication is critical as it forms the backbone for real-time data visualization and operational responses.

The versatility of HMIs significantly enhances user experience by transforming complex data into comprehensible visual formats. Operators can visualize process flows through intuitive dashboards and graphical representations, making it easier to detect anomalies and operational issues early on. The appropriate selection and configuration of these components are crucial, as they determine the overall effectiveness and reliability of the IHm Scada system in various operational environments.

Benefits of Implementing IHm Scada

The implementation of IHm Scada systems offers numerous benefits, including increased operational efficiency, reduced downtime, and enhanced safety measures. These systems facilitate rapid decision-making by providing operators with detailed data analytics and visual insights. Moreover, IHm Scada's ability to automate routine tasks minimizes human error and optimizes resource utilization, resulting in cost savings and improved productivity.

In addition to operational efficiencies, IHm Scada systems also enhance compliance with regulatory standards. Industries such as pharmaceuticals and food processing must adhere to stringent regulations regarding quality control and safety. IHm Scada systems can automate logging processes and generate reports that are crucial for ensuring compliance, significantly reducing the administrative burden involved in manual record-keeping. Additionally, by providing accurate real-time data, these systems can help companies avoid costly penalties related to non-compliance.

Furthermore, the scalability of IHm Scada solutions means that organizations can expand their systems as their needs grow. Whether it’s adding new machinery, incorporating new data sources, or globalizing operations, IHm Scada systems can be adjusted and enhanced without requiring a complete overhaul. This adaptability ensures that companies can remain agile in the face of industry changes and technological advancements, thus future-proofing their investments.

Challenges and Solutions

While the advantages are compelling, the deployment of IHm Scada systems is not without challenges. Issues such as data security and system integration can pose significant hurdles. As more devices become interconnected, the potential for vulnerabilities increases, making data security a paramount concern for many organizations. Cyberattacks targeting industrial systems are on the rise, making it essential for companies to adopt robust cybersecurity measures.

To address these challenges, industry experts recommend implementing multilayered security strategies, which may include firewalls, encryption techniques, and intrusion detection systems to monitor unauthorized access attempts. Regular security audits and updates to software are critical as they help identify vulnerabilities and mitigate risks. Training personnel in cybersecurity awareness is also vital, as human error often remains a weak point in system security.

In terms of system integration, the landscape of industrial automation often involves legacy systems that need to be connected with newer technologies. Selecting Scada systems that support multiple communication protocols can help in maintaining compatibility, and middleware solutions can facilitate smoother data transfers between disparate systems. Additionally, working with vendors who offer custom integration services can ensure that companies achieve a seamless transition to modernized systems without disrupting operational continuity.

Comparison Table: IHm Scada Features

| Feature | Description |

|---|---|

| Real-Time Monitoring | Enables live monitoring of industrial processes for timely interventions. |

| Data Acquisition | Collects and processes data from various sensors and equipment. |

| Alarm Management | Provides alert mechanisms to address potential system failures promptly. |

| System Integration | Facilitates the seamless integration with other industrial systems. |

| Historical Data Storage | Maintains a record of historical performance metrics for trend analysis. |

| Remote Access | Allows operators to monitor and control operations from remote locations. |

| User Management | Enables different permission levels for users to enhance security and control. |

FAQs

- What industries benefit most from IHm Scada systems? IHm Scada is widely used in sectors such as manufacturing, oil and gas, energy, water treatment, and transportation. These industries require robust monitoring and control systems to ensure safety, efficiency, and compliance with regulations.

- Can IHm Scada systems be customized? Yes, these systems can be tailored to meet specific industrial needs and constraints. Custom features can be developed based on operational requirements, allowing organizations to create a solution that aligns perfectly with their existing workflows.

- How does IHm Scada ensure data security? Implementing firewalls, encryption, and regular audits are standard practices to safeguard data within these systems. Additionally, employee training on best cybersecurity practices and incident response plans are crucial in creating a culture of security awareness.

- What is the role of HMIs in IHm Scada? HMIs provide users with graphical interfaces to monitor and control processes, enhancing usability and operability. They translate complex data into user-friendly visualizations, enabling operators to quickly ascertain the status of processes and act accordingly.

- How do Scada systems support predictive maintenance? By analyzing historical data and real-time performance metrics, IHm Scada systems can identify trends that indicate potential equipment failures. This proactive approach allows organizations to perform maintenance before critical failures occur, thus minimizing unexpected downtimes.

- What is the significance of remote access in modern Scada systems? Remote access capabilities enable operators and managers to oversee processes from various locations, which is particularly beneficial for organizations with multiple sites. This flexibility allows for quicker response times in emergencies and facilitates remote troubleshooting and adjustments.

The world of IHm Scada systems offers a complex yet rewarding landscape for those involved in industrial automation. By providing robust solutions for monitoring and control, these systems have become indispensable tools in enhancing productivity and ensuring safety across various industries. As technology continues to advance, the scope and capabilities of Scada systems will likely expand further, leading to even more innovative applications and improved operational outcomes.

The Future of IHm Scada Systems

Looking ahead, IHm Scada systems stand poised for transformation driven by advancements in technology and changes in industrial practices. The advent of IIoT (Industrial Internet of Things) is particularly significant, allowing for unprecedented levels of connectivity. As more devices come online, the data generated can be harnessed for deeper insights into operations, leading to enhanced predictive analytics and decision-making capabilities.

Moreover, the integration of artificial intelligence and machine learning within IHm Scada environments has the potential to revolutionize how data is processed and analyzed. AI can help identify patterns in data that may not be apparent to human operators, facilitating more precise predictions about system performance and potential failures. This layer of intelligence promises to further streamline operations and enhance efficiency, enabling organizations to respond proactively rather than reactively.

Another exciting development is the push towards more decentralized control mechanisms. Instead of relying solely on central control systems, edge computing allows data processing to occur closer to where it is generated. This can lead to reduced latency, faster decision-making, and a reduced burden on central systems. These advancements align with the growing desire for agility in industrial operations and can lead to the development of next-generation Scada solutions.

Furthermore, as the global economy increasingly emphasizes sustainability, IHm Scada systems will play a critical role in helping industries reduce their carbon footprint. By improving energy efficiency, waste management, and compliance with environmental regulations, these systems can support companies in achieving their sustainability goals. In conclusion, the evolution of IHm Scada systems is a testament to the critical role they play in the industrial landscape. By adopting technological advances and aligning with market demands, organizations can leverage these systems to drive innovation, enhance operational efficiency, and contribute to a sustainable future.