Understanding the Valvula Dosadora

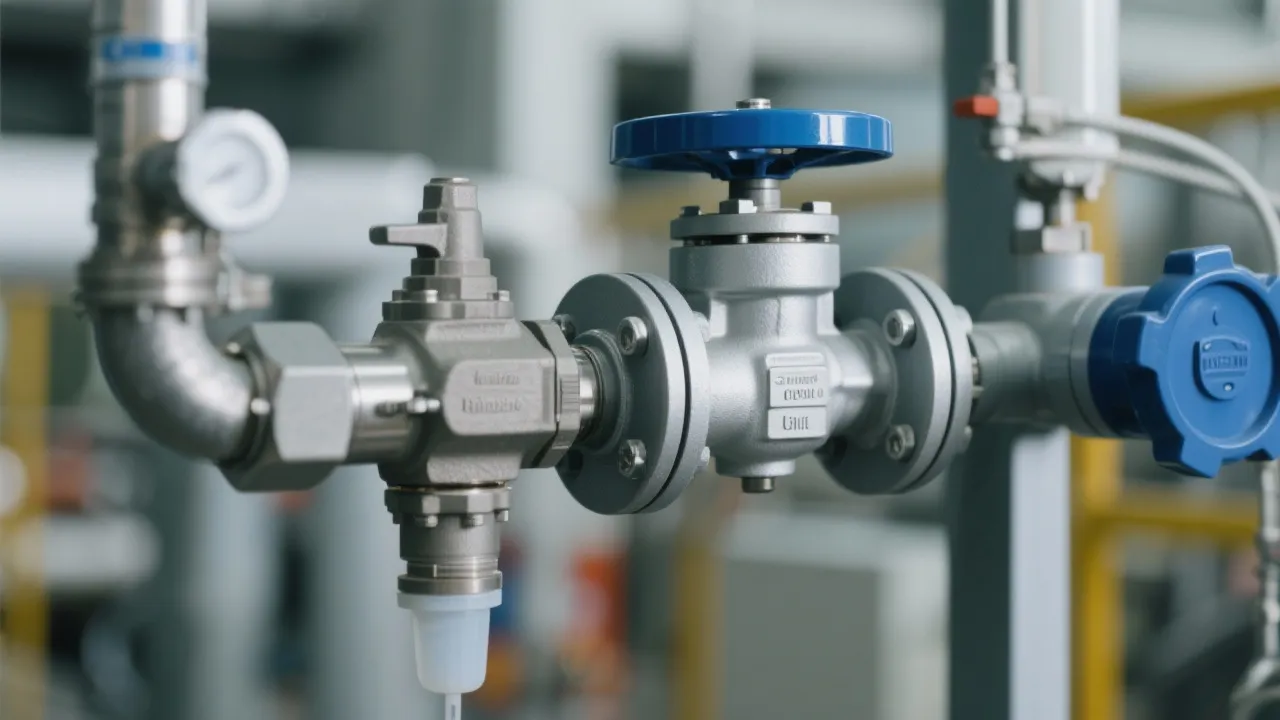

This article delves into the function and importance of the "Valvula Dosadora" in industrial applications. These devices are crucial for the precise control and measurement of fluid, essential for maintaining efficiency and safety in various processes. While they may seem niche, dosing valves are integral across numerous industries, ensuring that operations run smoothly and effectively.

The Importance of the Valvula Dosadora in Industry

In industrial contexts, the Valvula Dosadora plays a fundamental role in managing and distributing fluids with precision. These devices are essential for industries such as pharmaceuticals, food and beverage, and chemical processing, where precise measurement is critical. By effectively controlling the volume of liquid dispensed, these valves help ensure product consistency and quality.

In an era where efficiency and accuracy dictate operational success, the valvula dosadora surfaces as a pivotal piece of equipment. Moreover, as industries evolve, there is an increasing demand for sophisticated systems that not only manage flow rates but also integrate seamlessly into computerized controls, thereby enhancing overall production efficiency. The valvula dosadora does not merely function as a dispensing tool; it embodies advanced engineering and technology that align with contemporary industrial needs.

For instance, in the pharmaceuticals sector, a small error in liquid dosing could result in ineffective medication or, worse, adverse health effects. Thus, the role of the valvula dosadora extends beyond just measurement; it is a safeguard for clinical integrity and patient safety. In the food and beverage industry, maintaining flavor consistency and quality control relies heavily on accurate dosage controls, making these valves indispensable for product reliability and brand trust.

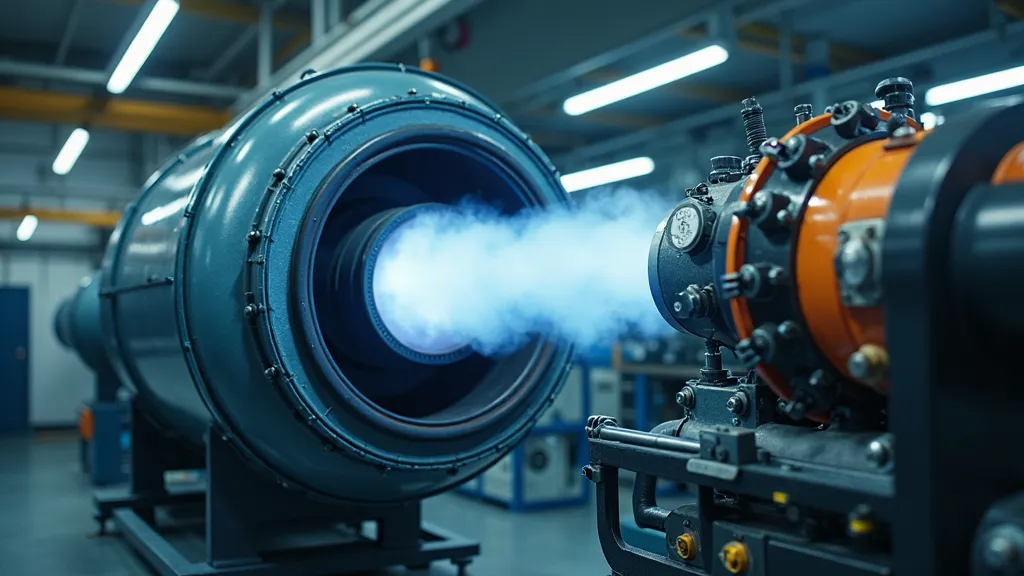

How a Valvula Dosadora Works

The Valvula Dosadora operates by regulating the flow of liquid based on specific measurements. They are designed to handle various fluid viscosities and flow rates, adapting to the specific needs of an industry. Advanced models are often equipped with sensors and digital interfaces, allowing for real-time adjustments and remote control.

A basic understanding of the mechanics can shed light on these devices' functionality. At its core, a valvula dosadora works through the manipulation of pressure differentials and valve opening durations. When prompted by a signal from its control system — which may be a simple manual switch or a sophisticated digital system — the valve opens for a predetermined duration, allowing fluid to pass through. The speed of the pump, the valve's opening size, and the viscosity of the liquid govern how much liquid flows through.

Modern valvula dosadora systems may also integrate features such as flow meters, which provide real-time data and feedback to the operating system. This allows operators to monitor and adjust flow rates dynamically, ensuring that any variances are corrected on the fly. For example, varying fluid temperatures can affect viscosity and thus flow rates; advanced systems compensate automatically, maintaining accuracy even under changing conditions.

Additionally, many advanced models utilize programmable logic controllers (PLCs) or computer systems for automation, which can include features such as batch processing, pre-set dosing metrics, and safety interlocks to prevent over-dispensing. These innovations not only enhance precision but also improve operational safety, minimizing risks related to human error and equipment malfunction.

Benefits and Applications

- Ensures accuracy in fluid dispensing, reducing waste and optimizing processes.

- Enhances safety by minimizing the risk of leaks and overflows.

- Flexibility in use across multiple sectors, from manufacturing to biotech.

- Contributes to cost savings through efficient resource use and reduced downtime.

- Facilitates compliance with industry regulations, especially in sensitive sectors such as pharmaceuticals and food production.

The versatility of the Valvula Dosadora allows for its application across numerous fields and industries. In the food and beverage sector, these valves are commonly used in processes such as mixing ingredients, filling containers, and controlling flavors or preservatives by accurate dosing. For instance, in brewing, a precise amount of hops or sugars must be added to achieve the desired flavor profile, which the valvula dosadora can deliver with remarkable accuracy.

In chemical processing, the ability to accurately dispense various reactants is essential for producing high-quality products while minimizing waste and ensuring worker safety. Any error in dosing could lead to suboptimal reactions, harmful spills, or even hazardous situations, thereby reinforcing the critical nature of reliable dosing systems.

Likewise, in biotechnology research, where precise quantities of various reagents must be accurately administered in experiments, the significance of valvula dosadora is profound. Here's where automated systems earn their keep, enabling researchers to focus on the experimentation rather than manual measurement, which could introduce variability and error into results.

Valvula Dosadora Selection Criteria

When selecting a Valvula Dosadora, consider the following criteria:

| Criteria | Considerations |

|---|---|

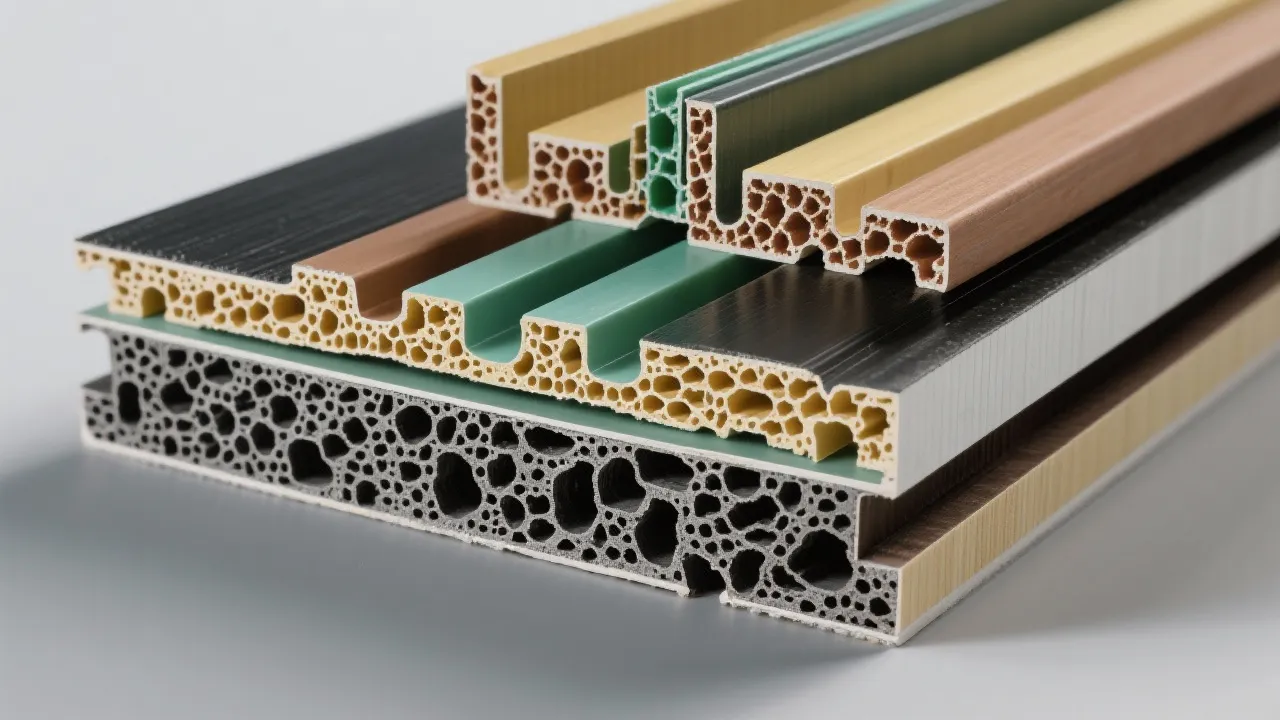

| Material | Choose materials that are compatible with the fluid being handled. Rigid plastics may be perfect for certain chemicals, while stainless steel is often preferred in food processing due to its smooth surface and corrosion resistance. |

| Flow Rate | Ensure that the valve can handle the required flow rate for your application. This requires an analysis of expected production rates and the potential need for scaling operations in the future. |

| Control Method | Decide between manual or automated control based on operational needs. Automated systems may require a higher initial investment but can greatly enhance efficiency and precision. |

| Precision Level | Evaluate the precision requirements to maintain process quality. For applications where even slight variances can impact product safety or effectiveness, higher-precision valves are indispensable. |

| Maintenance Requirements | Investigate the maintenance requirements of the valve. Some models offer easy access for cleaning and repairs, which can drastically reduce downtime. |

| Integration with Existing Systems | Consider how well the valvula dosadora will integrate with existing equipment and control systems to ensure smooth operation and reduce compatibility issues. |

Each of these criteria deserves careful consideration. For instance, in food processing, where contaminants can drastically affect product safety, the material choice becomes paramount. Stainless steel or specialized food-grade plastics are often required to ensure hygiene standards are met. Meanwhile, in chemical processing industries, additional resistance to corrosion can dictate material selection, ensuring that valves endure over time without degrading.

Moreover, precision levels must be well defined early in the selection process. Different applications will have diverse requirements; varnishes and inks may require relatively modest precision, while pharmaceutical manufacturing may call for exceedingly high levels of dosing accuracy and repeatability. In such cases, selecting a highly reliable and repeatable valvula dosadora could be considered less of an operational choice and more of a regulatory necessity.

Further, it is helpful to engage with manufacturers or suppliers who offer comprehensive support, including guidance on setup, troubleshooting, and routine maintenance. The long-term performance of the valvula dosadora can depend significantly on how well it's maintained and integrated into existing systems. Regular checks and calibrations will help uphold precision and reliability over time.

The Evolution of Valvula Dosadora

As industries advance, so do the technologies behind valvula dosadora. The trend towards Industry 4.0 has prompted the development of smart valves that come equipped with IoT capabilities. These innovations allow for remote access and monitoring, predictive maintenance options, and data logging capabilities, which enhance operational intelligence. Users can monitor system performance in real time, receiving alerts if the system drifts from set parameters, thereby preemptively addressing potential issues before they escalate into costly downtime or safety incidents.

Moreover, the development of machine learning algorithms provides the opportunity to optimize fluid dispensing processes based on collected data. By analyzing past dispensing performance, these systems can adjust parameters to enhance accuracy further. Companies can gain insights on when to perform maintenance, averting unexpected failures and extending the lifespan of the equipment. Such transformations are rapidly changing the landscape of industrial operations, enabling businesses to operate more efficiently and responsively.

Conclusion

As an expert in industrial solutions, it's crucial to understand the technology and implementation of the Valvula Dosadora. Its role in ensuring process accuracy cannot be underestimated, making it indispensable for maintaining the high standards expected in modern industries. The evolution of this technology demonstrates a clear trajectory towards smarter, more integrated systems that will empower industries to become more agile and responsive to market demands.

Investing in the right valvula dosadora not only enhances operational efficiency but ensures compliance with increasingly stringent industry regulations regarding safety and product consistency. As the applications of these valves continue to expand, businesses that prioritize precision and automation will likely retain a competitive edge in their respective markets, driving innovation and operational excellence.

FAQs

- What industries use Valvula Dosadora? - These valves are prevalent in sectors that require precise fluid control, such as pharmaceuticals, food processing, and chemical manufacturing. Their adaptability enables a wide variety of applications, including paint manufacturing, HVAC systems ducting, and even in water treatment processes where precise chemical dosing is essential.

- Can these valves handle all types of fluids? - They are designed for a wide range of viscosities, though material selection is critical for compatibility. Some specialized valves may be required for handling corrosive or highly viscous liquids, ensuring that the appropriate design is considered for the specific fluid type in use.

- What factors influence the choice of Valvula Dosadora? - Considerations include material compatibility, flow rate capacity, control mechanism, precision level needed, maintenance requirements, and integration capabilities with existing systems. The complexity of the process can also influence the choice, leading to custom or bespoke solutions tailored to unique operating conditions.

- How does maintenance affect the performance of Valvula Dosadora? - Regular maintenance ensures the continued accuracy and reliability of dosing operations. It prevents wear and tear, addresses minor issues before they escalate, and promotes the longevity of the system. Neglecting maintenance can lead to increased downtime and inaccurate dispensing, ultimately impacting product quality and operational efficiency.

- Are there energy-efficient options available in Valvula Dosadora systems? - Yes, many contemporary models are designed with energy efficiency in mind, utilizing technology that reduces energy consumption while maintaining performance. This aspect is particularly important as more businesses prioritize sustainability and aim to reduce their overall carbon footprint.

- What is the future for Valvula Dosadora technology? - The future points towards greater automation, integration with AI for predictive maintenance, and enhanced monitoring capabilities via IoT. As industries continue to evolve towards smarter manufacturing, the role of valvula dosadora will expand to meet growing demands for efficiency, safety, and reliability in fluid handling.