Understanding Dosing Valves in Industry

The dosing valve, or "válvula dosadora," is a crucial component in various industrial processes, offering precise control over the flow of materials. Its applications range from chemical manufacturing to food processing, where accurate dosages are essential. This article delves into its significance, functionalities, and best practices for utilization, providing a comprehensive guide for industry professionals.

Introduction to Dosing Valves

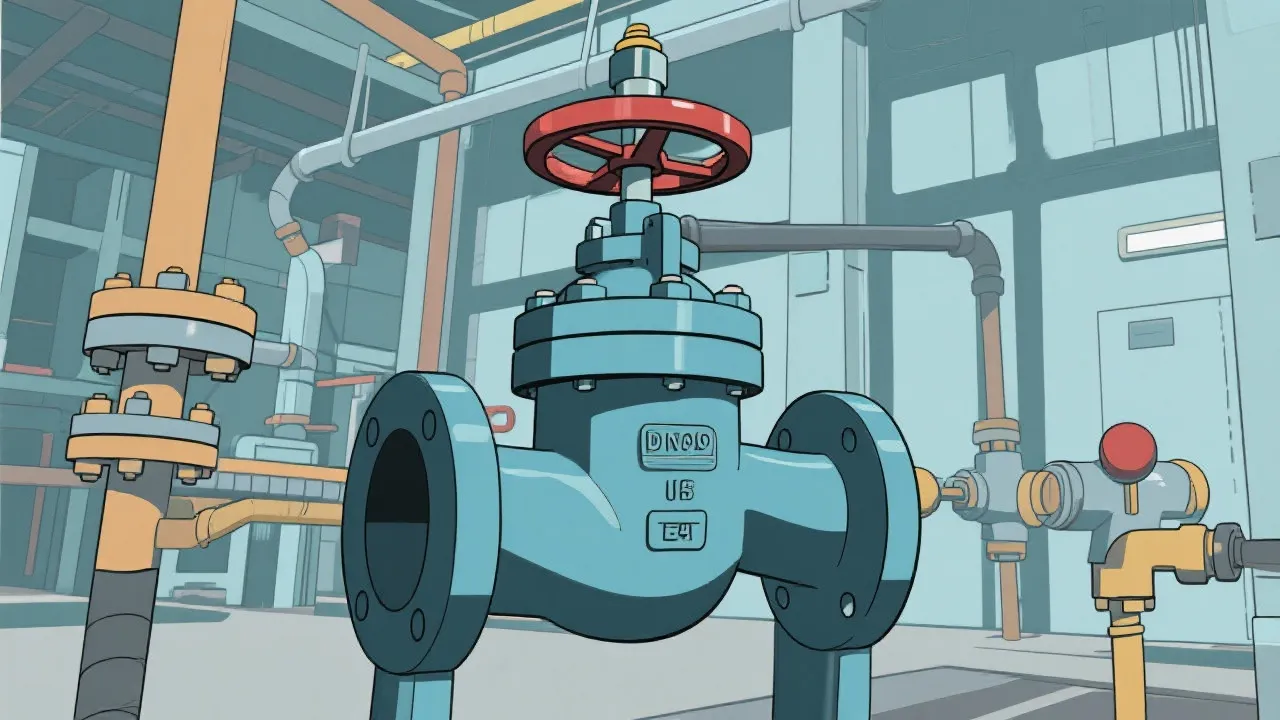

The válvula dosadora, or dosing valve, serves as a pivotal instrument in industrial systems by allowing precise measurement and control of liquid or gas flow. Essential in various sectors, from pharmaceuticals to food production, these valves ensure that exact quantities of substances are released into a process, maintaining product quality and efficiency. Given the intricate nature of modern manufacturing, the significance of accurate dosing has grown substantially, requiring advanced valve technologies that can deliver precise control in increasingly complex operational environments.

Key Functions and Benefits

At the core, dosing valves are designed to provide accuracy in volume delivery and regulation. This level of control is critical when dealing with components that require specific proportions, preventing excess or insufficient use of materials, which can lead to waste or compromised product integrity. A dosing valve's precision not only enhances product quality but also optimizes resource utilization, making processes more sustainable and cost-effective.

Additionally, these valves contribute to maintaining consistent production rates and reducing downtime caused by manual adjustments. By automating the dosing process, industries can achieve higher throughput and reduced variability in product quality due to inconsistent dosing. The reduction in variations translates into more predictable manufacturing cycles, leading to enhanced overall efficiency and reliability in production systems.

Moreover, dosing valves can significantly minimize labor costs associated with manual interventions, especially in large-scale operations where high volumes of materials must be managed accurately. By integrating advanced control systems into these valves, businesses can ensure that their dosing operations are not only precise but also adaptable to changing production requirements.

Design and Operation

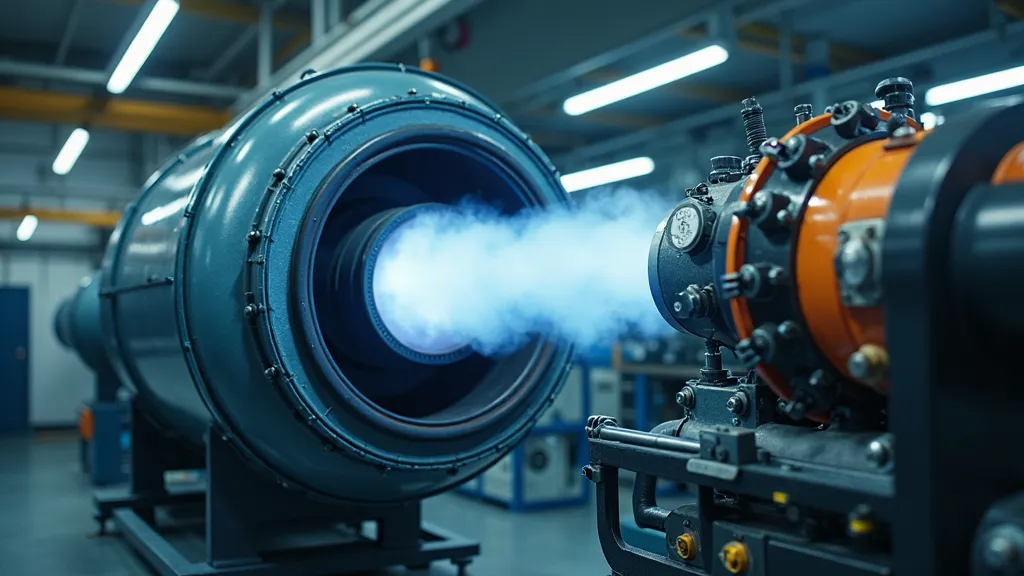

Generally, a válvula dosadora consists of a body, actuator, diaphragm, and seat. The actuator controls the valve by either manual means or automated systems, adjusting flow rates as necessary. Modern dosing valves often incorporate sensors and electronic controls for enhanced precision, allowing integration with smart manufacturing technologies. This integration includes the use of programmable logic controllers (PLCs) and Internet of Things (IoT) devices, guiding systems toward enhanced data collection and process monitoring capabilities.

The key components of a dosing valve include:

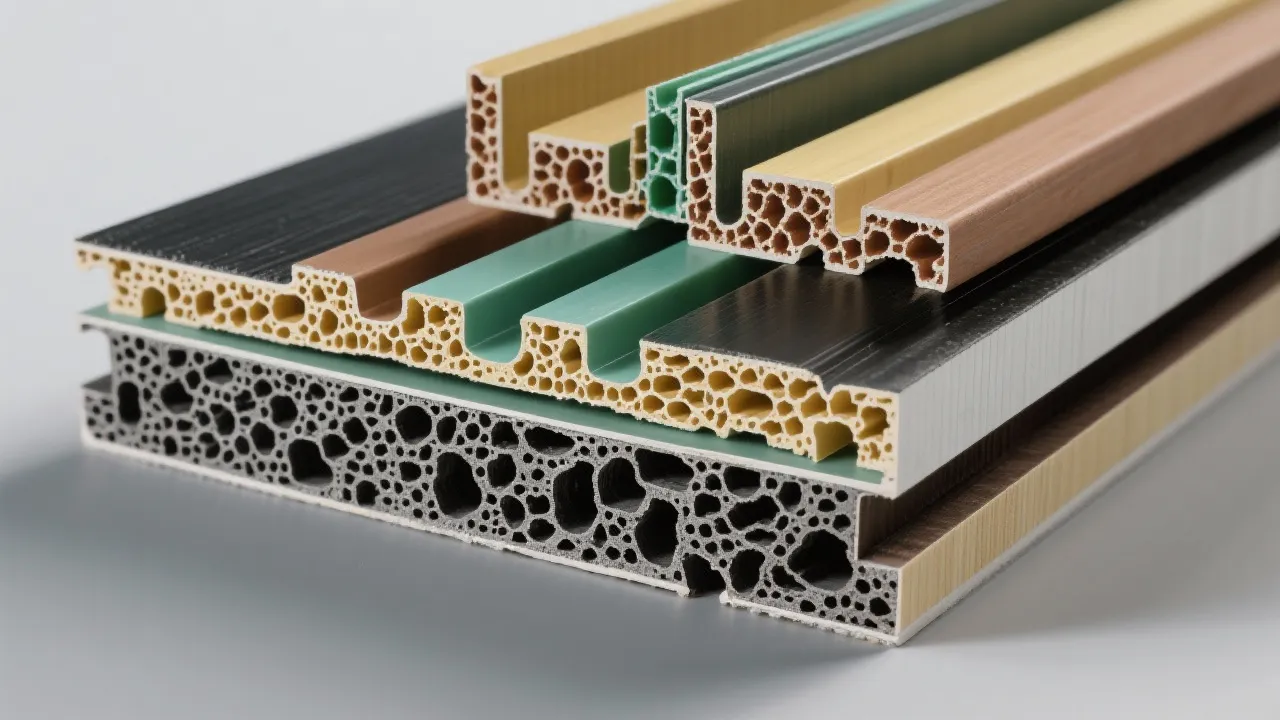

- Valve Body: This part holds the internal components and is designed to withstand the pressures and temperatures of the specific application.

- Actuator: Depending on the application, actuators can be electric, pneumatic, or hydraulic, enabling the valve to open or close as needed.

- Diaphragm: This flexible membrane allows for smooth operation, creating a seal that prevents leakage while controlling flow dynamics.

- Seat: The interaction between the diaphragm and seat determines the precision and reliability of the valve's operation.

Enhanced designs now also incorporate features like adjustable flow restrictors, multiple inlet and outlet connections, and quick-release mechanisms, which facilitate easier maintenance and enhance operational efficiency across different sectors.

Applications Across Industries

Dosing valves are used extensively in various industries, reflecting their versatility and the critical role they play in ensuring quality and consistency:

- Pharmaceutical Industry: Ensures accurate dosage of active ingredients, maintaining strict compliance with regulatory standards. The precision in dosing is crucial not only for efficacy but also for patient safety, where overdosing or underdosing can have severe consequences.

- Food and Beverage: Facilitates the consistent addition of flavors, colors, and other ingredients, upholding quality and taste. In this sector, dosing valves help prevent discrepancies in flavor and texture that can detract from consumer experience.

- Water Treatment: Controls the quantity of additives such as coagulants and disinfectants, ensuring safe water quality. Precise dosing in water treatment is essential for both environmental protection and public health, underscoring the importance of reliable dosing technology.

- Chemical Industry: Helps in mixing chemicals in precise ratios, preventing chemical imbalances or hazards. In chemical manufacturing, even minor discrepancies can lead to process inefficiencies or dangerous reactive situations, emphasizing the need for advanced dosing solutions.

- Agriculture: Dosing valves are also applied in agricultural settings to control the precise application of pesticides, fertilizers, and other treatments. Accurate dosing is essential in agriculture to optimize crop yields while minimizing environmental impact.

- Textile Industry: Dosing valves are utilized to regulate the flow of dyes and chemicals in the textile manufacturing process, ensuring consistent colors and quality in the finished products. This accuracy in application not only ensures market competitiveness but also contributes to sustainable practices by minimizing waste.

Comparison of Leading Suppliers

| Supplier | Unique Features |

|---|---|

| Supplier A | Innovative self-cleaning mechanism and high-temperature tolerance, making them suitable for extreme environments found in the chemical and pharmaceutical sectors. |

| Supplier B | Automated control systems and customizable flow rates, allowing for seamless integration into larger process control systems, ideal for dynamic production environments. |

| Supplier C | Cost-effective solutions with durable materials and low maintenance needs, catering to industries where budget constraints are a significant consideration without sacrificing quality. |

| Supplier D | Advanced telemetry systems and data analytics capabilities, providing real-time monitoring and operational insights for predictive maintenance and process optimization. |

As industries increasingly favor suppliers that provide not only equipment but also technology and support services, the competition among manufacturers is shifting towards offering innovative solutions that enhance the operational efficiency of dosing systems.

Installation and Maintenance Tips

Proper installation and regular maintenance of the válvula dosadora are vital. During installation, it is crucial to ensure that the valve is compatible with the material's properties (temperature, pressure, corrosive nature). Incorrect installation can cause leaks or failures, leading to production downtime and safety hazards. Following the manufacturer's specifications for installation and adhering to any industry standards is essential for optimal valve performance.

Regular maintenance checks should focus on inspecting seals, checking for leaks, and verifying calibration settings to maintain performance efficiency. The following maintenance practices can help extend the lifespan and reliability of dosing valves:

- Routine Inspections: Conduct routine inspections for leaks and signs of wear, particularly on seals and moving parts. Early detection of issues can prevent catastrophic failures.

- Calibration Verification: Periodic calibration checks ensure that the doses being dispensed are within specified tolerances, which is crucial in regulated industries like pharmaceuticals and food.

- Cleaning Procedures: Implement a cleaning routine to remove any residue build-up that may affect the valve's performance. Cleaning might involve flushing the system with appropriate solvents or cleaning agents that are compatible with the materials being processed.

- Training Staff: Ensure that all staff members who interact with dosing valves are well-trained on operational and maintenance protocols. Their understanding of the equipment and adherence to best practices plays a critical role in maintaining system integrity.

Maintaining detailed records of all maintenance performed, including inspections, repairs, and replacements, can help track valve performance over time and facilitate troubleshooting should issues arise.

FAQs

1. Why is a dosing valve essential in industrial processes?

Dosing valves provide precise control over material flow, ensuring accuracy in production, minimizing waste, and maintaining product quality. Their role is particularly vital in applications where deviations in material ratios can lead to compromised safety or quality.

2. How often should dosing valves be maintained?

Routine maintenance should be conducted every 6 to 12 months, depending on the application's demands and valve usage frequency. In high-use environments or applications with strict regulatory requirements, more frequent maintenance may be warranted.

3. Can dosing valves handle both liquids and gases?

Yes, dosing valves are versatile and can be used for both liquid and gas applications, provided the valve materials are suitable for the specific media. Compatibility with the process materials is critical to preventing corrosion and ensuring reliable operation.

4. What factors should be considered when selecting a dosing valve?

When selecting a dosing valve, consider factors like the type of material (liquid or gas), process pressure and temperature, required flow rates, materials of construction, and regulatory compliance needs. Evaluating the operational environment is also crucial to ensure reliability.

5. How can technology enhance the performance of dosing valves?

The integration of smart technologies, like IoT and machine learning, can enhance the performance of dosing valves by enabling real-time monitoring, predictive maintenance, and data-driven adjustments to optimize dosing accuracy and efficiency.

Conclusion

The importance of the válvula dosadora cannot be overstated in today's industrial settings. Its role in ensuring accuracy and efficiency across various applications underscores the need for careful selection, installation, and maintenance. As industries continue to evolve, so too will the technology behind dosing valves, further enhancing their capabilities and applications.

With the transition towards more automated and digitized manufacturing processes, the demand for high-performance dosing valves is expected to increase. Suppliers are likely to continue innovating, introducing features that not only improve reliability but also data integration and predictive capabilities. This evolution will pave the way for dosing valves that not only meet current operational demands but also anticipate future needs, setting the foundation for advanced manufacturing systems that prioritize efficiency, sustainability, and precision.

As the landscape of manufacturing processes changes rapidly, the dosing valve will remain an essential tool, instrumental in achieving the high standards of accuracy and efficiency that modern industries require. Furthermore, the focus on sustainability and environmental responsibility will likely shape the development of dosing technologies, leading to greener and more efficient practices across all sectors. This continual advancement not only supports business objectives but also contributes to global efforts in fostering sustainable industrial practices.